The ultimate guide to forklifts

Forklifts, also known as lift trucks, are essential machines used across various industries for material handling, lifting and transporting heavy...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Many of the machines you use on a daily basis have seat belts. We all know that cars and trucks require seat belts and that you need to use them, not only for the health & safety of you and your family, your co-workers and so on but also to help you avoid the wrath of your local police force.

When it comes to machinery it is not so obvious. As a result I am regularly asked the question, does my machine need a seat belt?

In short there are only two reasons why a machine needs a seat belt –

Laws, standards or codes of practice mandate that a seat belt is required

It is a risk control, implemented to manage the risk associated with a hazard

Let’s look at these two reasons in more detail. The first reason is quite straight forward, seat belts in cars and trucks are mandated by the Australian Design Rules (ADRs) which every car and truck in Australia must comply with. It’s the law.

The WHS laws have indirect requirements for seat belts too. Clause 214 (a) & (c) of the WHS Regulations state the following –

214 Powered mobile plant—general control of risk

The person with management or control of powered mobile plant at a workplace must in accordance with Part 3.1, manage risks to health and safety associated with the following:

(a) the plant overturning,

(b) things falling on the operator of the plant,

(c) the operator being ejected from the plant,

(d) the plant colliding with any person or thing,

(e) mechanical failure of pressurised elements of plant that may release fluids that pose a risk to health and safety.

When a machine is fitted with a Rollover Protective Structure (ROPS). A seat belt is required to keep the operator within the “envelope” of protection that a ROPS creates.

The second reason is a little less direct however arguably more important to understand. Controlling the risk is the 3rd step in the risk assessment process. The steps are well documented –

Identify the hazard

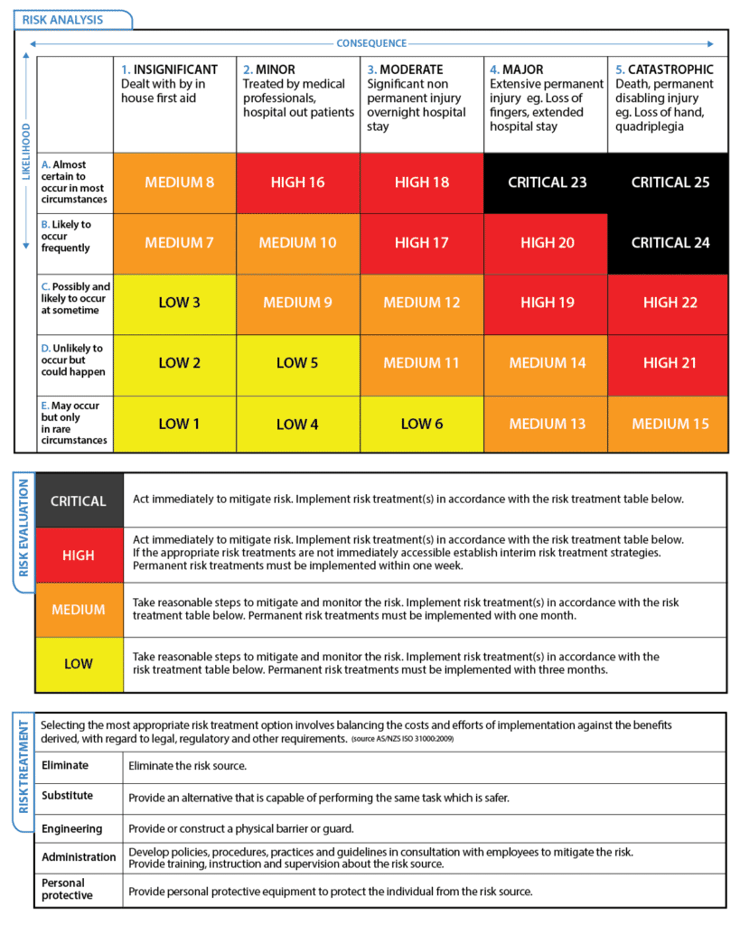

Assess the risk (consequence vs likelihood)

Control the risk

Monitor

Let’s walk through an actual example of how this works. Does a piling machine require a seat belt? The international standard does not mandate a ROPS. The machine is capable of tipping on its side. If the machine tips on its side there is a potential crush hazard if the operator was caught between the machine and the ground.

Using the risk assessment steps as above –

Identify the hazard – There is a hazard, it is crushing

Assess the risk – The consequence is potentially a fatality and the likelihood is unlikely but could happen (High 21 on the risk matrix that Plant Assessor uses therefore we must mitigate the risk immediately)

Control the risk – What control can we put in place using the hierarchy of risk control that will best control the risk. We cannot eliminate the risk source, we cannot substitute the machine with another that is safer, we put in an engineering control, in this case an operator restraint, a seat belt

Monitor – Check seat belt daily as part of pre start checklist

If you have any questions please contact our friendly team by calling 1300 728 852.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Forklifts, also known as lift trucks, are essential machines used across various industries for material handling, lifting and transporting heavy...

We all know machinery and its operation can be inherently dangerous.

The Queensland Government has changed regulations relating to the use of quad bikes in workplace settings within the state.