A risk assessment is a mandatory part of satisfying compliance obligations: they keep your machines and people safe.

But getting it right can be a headache. Risk assessments take time, require expert knowledge of legislation and machinery – and often don't give any method of controlling identified risk and hazards.

Ideagen Plant Assessor makes it simple to identify, assess, and control hazards through step-by-step, machine-specific risk assessment that cut out the guesswork.

Have confidence that your risk assessment process is thorough and consistent, hazard controls are relevant, and you’re compliant to the latest letter of legislation.

Select and inspect. Machine risk assessments made easy

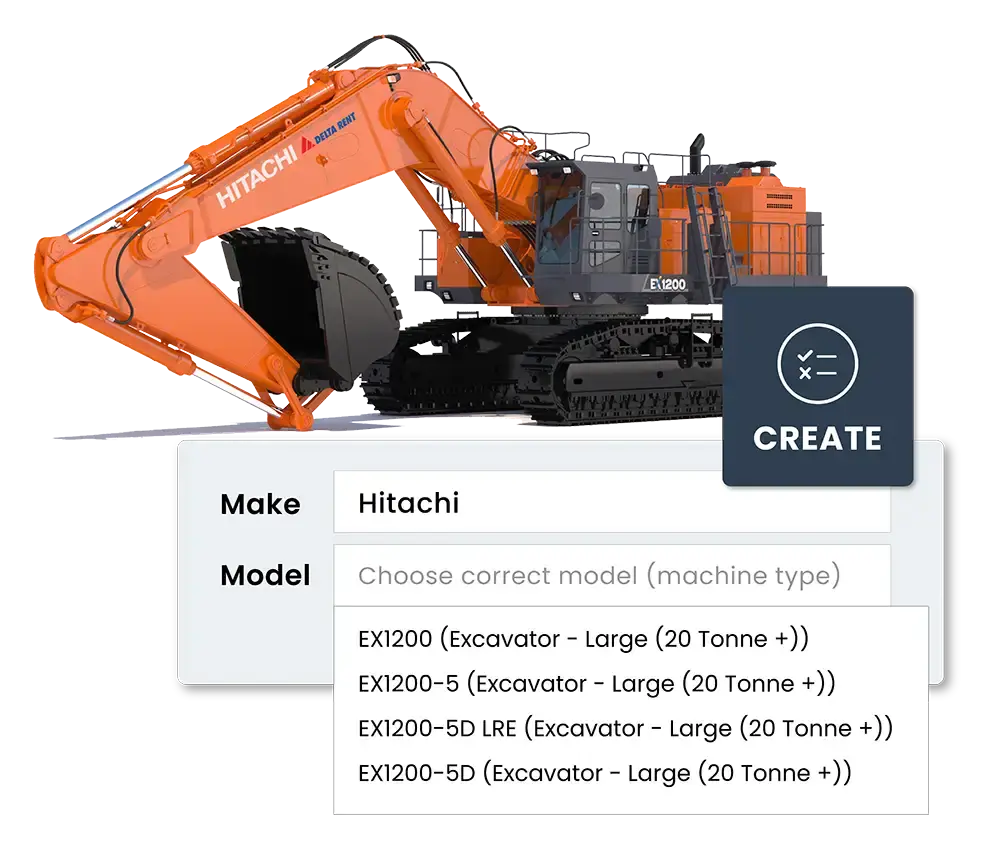

Powered by the Machinery Compliance engine (MCE) developed to automate the identification of machinery hazards, set risk ratings and provide applicable control measures per referenced legislation. All you need to do is select your machine, answer the inspection questions and let the MCE do the risk analysis for you.

|

Prior to using Plant Assessor, we had struggled with several risk assessment templates. One of our suppliers suggested that Plant Assessor was an effective program for developing detailed risk assessments that were recognised by blue chip clients.” - Mick Carr, Plant Maintenance Superintendent, Ertech |

Specific to each machine

The MCE database contains over 120,000 makes and models of equipment providing you with a comprehensive non-generic risk assessment that is relevant to each machine. The easy to follow surveys provide consistency across your fleet assessments, reduce subjectivity and give clear actions for meeting compliance.

|

The Plant Assessor process is regimented and thorough, whilst being simple and easy to follow. Anyone can use it as long as they understand the plant well and have reasonable comprehension skills.” - Jason Hudson, Safety Manager, Hunt8r Alliance |

Know the risks, and put control measures in place

Once you’ve completed an Ideagen Plant Assessor risk assessment, you’ll receive an instant risk management report providing hazard controls that are relevant to your machine, reflect the latest updates to legislation and standards, and help satisfy your compliance and safety obligations.

Learn about our Risk Management Reports

|

The team have stayed very active in dealing with the day-to-day aspects of ensuring the system remains central to all machinery related activity. They ensure any issues are flagged, procedures to rectify are followed and outcomes are recorded.” - Brian Olsen, Group Safety Manager, BMD |

We've done the legislative legwork

Our risk assessments consider all WHS & OHS Acts, Regulations, Codes of Practice, Australian and International Standards as well as industry best practices, so you can be sure that the risk report generated at the end is up to date with the latest in legislation.

|

[Ideagen Plant Assessor] provides consistent questions for the asset that meet legislation, Australian standards and codes of practice. Without that it’s up to the individual to decide what the risks are.” - Richard Thompson, Workshop and Operations Program Leader, Logan City Council |

Machine-specific risk assessments, fit for purpose:

.jpg)

01

Signup to Ideagen

Plant Assessor

02

Add a machine

03

Click 'Create

Assessment'

04

Answer pre-defined

questions

OutcomeReceive your ready to action Risk

|

|

Learn more about Risk Management Reports

Frequently asked questions

-

What is a machine risk assessment?

A machine risk assessment is a systematic fleet management process used to identify, evaluate, and mitigate potential hazards associated with machinery and equipment in the workplace.

During a machinery risk assessment, hazards are identified, their likelihood and severity are assessed using a risk matrix and the hierarchy of control measures is followed to minimise or eliminate risks.The goal of the assessment is to ensure that machinery is operated safely, and that appropriate measures are in place to protect workers from harm. The risk assessment process should be conducted regularly to maintain a safe working environment.

-

How do Ideagen Plant Assessor risk assessments differ from other risk assessments?

Ideagen Plant Assessor's risk assessments are the most time efficient and easiest way to determine whether your plant is safe and compliant. With built-in legislation and machinery expertise, our Machinery Compliance Engine (MCE) automates the identification of hazards, applies risk ratings, and recommends required controls to mitigate each hazard and improve your machine’s safety. That’s why Ideagen Plant Assessor is the leading risk assessment software for machinery risk management and compliance.

All of Ideagen Plant Assessor’s risk assessments are:

-

Easy to complete and understand – they are built for anyone to complete. Simply answer yes, no or not applicable on all risk assessment questions.

-

Thorough – including plenty of questions to ensure all aspects of your plant are assessed.

-

Digital – providing you with a digital library in the cloud to store all your previous risk assessments and other relevant machinery documents.

-

Built upon industry knowledge, legislation, standards and regulations – offering you a unique product that gives you peace of mind that you’re thoroughly checking your machine’s compliance. We know it so you don’t have to.

-

Machine specific – select your exact machine from a database of over 120,000 pieces of plant and equipment so you know all the intricacies of your unique machine have been assessed.

-

Offer corrective actions – a full Risk Management Report of any actions that need to be taken to improve your machine’s safety and compliance is collated for you following the completion of the assessment.

-

Objectively signed off – an objective person may sign off on the risk assessment following its completion.

-

-

Do you offer a machinery risk assessment template?

No, we do not offer a machinery risk assessment template. Our risk assessment software provides pre-built assessment surveys that do not require users to build out their assessments. Users can simply select their machine make and model, and they will have instant access to a comprehensive assessment survey that references all applicable legislation, is specific to their machine and ready to inspect their machine right away.

-

What is a risk management report?

After completing an Ideagen Plant Assessor risk assessment, our sophisticated Machinery Compliance Engine (MCE) instantly identifies the hazards, applies a risk rating that is based on the likelihood that the event will occur, and the potential impact it could have. It then provides recommended corrective actions to help mitigate risk and meet compliance.

Each risk management report generated considers all legislative requirements, Australian Standards, Codes of Practice and industry best practices, ensuring confidence in compliance across your entire fleet.

-

Can I save time with Ideagen Plant Assessor risk assessments?

Yes, you can save time with Ideagen Plant Assessor's risk assessments. Our machinery safety software platform not only provides pre-built assessments that are quick and easy to use by selecting your machine's make and model, but we also automate the risk analysis post-assessment through a risk management report.

Our Machinery Compliance Engine (MCE) identifies the hazards, applies the risk ratings, and recommends control measures needed to mitigate risk. All of this information is provided in an instantly generated risk management report, streamlining the entire process and saving you valuable time.

GET A DEMO

See first hand how we can solve your machinery compliance headaches

Machine-specific risk assessments

Automated risk reports

Recommended hazard controls

Real-time machine safety status

Legislation laws covered

Clear action plan to compliance

Related Resources

ARTICLE

Top 10 most assessed machines in Plant Assessor for 2023

A total of 67,891 risk assessments were carried out on a variety of machines across the year. But which machine types were the most assessed?

ARTICLE

What are machinery codes of practice and why should I follow them?

We delve into exactly what machinery codes of practice are, what they cover and why you should follow them.

.png?width=1040&height=618&name=008%20Webinar%20Email%20Header%20(640%20x%20380%20px).png)

WEBINAR

From Subjectivity to Consistency: The Future of Risk Assessments with Ideagen Plant Assessor

Let us walk you through a live product demonstration of how our Machinery Compliance Engine (MCE) can save you time, reduce subjectivity and provide consistency across your machinery risk assessment processes.

ARTICLE

What's the difference between a hazard and a risk in machinery safety?

Understanding the difference between them is crucial for maintaining safe working environments.