Split rims guide

Updated July 2024

In this guide:

Maintenance and safety practices for split rims

Removal and installation of split rims

What is a split rim?

A split rim is a wheel assembly consisting of multiple pieces joined together by bolts or a lock ring. They are widely used across various heavy machinery and equipment such as lift trucks, earthmoving machinery, trucks, buses and trailers. Split rims are compatible with both pneumatic and solid tires.

Identifying split rims

Split rims are typically different to those that you would find on cars or light vehicles. These rims are a single metal piece with the tyre inflated around it. Split rims however are multi-piece or divided, held together by bolts or a lock ring. They will commonly feature two sets of bolts; one set secures the wheel assembly to the hub (wheel nuts), while the other set fastens the split rim components together. This distinctive design helps differentiate split rims from other types of wheel assemblies.

Photo of split rim showing both sets of bolt holes

(image courtesy of www.weiku.com)

A typical split rim assembly

(image courtesy of SafeWork NSW)

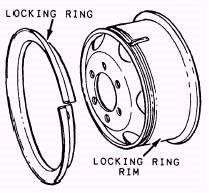

Another type of split rim has a bead that sits between the rim and the tyre. This is known as the lock ring and will have a gap in it (see images below).

Locking ring diagram

(image courtesy of www.tpub.com)

Locking ring

Hazards of split rims

Split rims have additional risks compared to traditional wheel assemblies, primarily due to the potential for sudden release of compressed air when handling or servicing tires. This release can forcefully propel components at high speeds, posing serious danger to operators and bystanders.

Each year, incidents occur where individuals are fatally injured or seriously harmed during tire inflation or when dismantling split rim assemblies. During operation, stresses and wear experienced by wheel components can lead to fatigue and the development of cracks or other structural weaknesses. If left, these faults can result in catastrophic failure of the rim or wheel.

Maintenance and safety practices for split rims

Owners and operators of equipment fitted with split rims are advised to conduct regular inspections of wheel and rim assemblies. Any signs of damage or wear should be quickly identified, marked and reported. This proactive approach helps mitigate risks associated with potential structural failures.

Removal and installation of split rims

Only trained and competent persons should undertake the removal and installation of split rims. Prior to handling split rims, it is essential to ensure and adhere to safe work procedures, while also following the manufacturer's guidelines for wheel removal, tire inspection, rim disassembly and assembly and installation.

When dealing with pneumatic tires mounted on split rims, it is crucial to deflate the tire before loosening any fasteners to remove the split rim. For vehicles with dual wheels, both tires should be deflated to prevent damage, as the inner wheel may be compressed against the outer wheel. After disassembly, all components of the wheel assembly must be thoroughly cleaned and inspected for cracks, deformation, corrosion and wear. Non-destructive testing may be necessary to detect hidden faults and cracks in some components.

Inspect tires for defects before fitting them on the rim and ensure that the torque used to secure the rim halves complies with the manufacturer's recommendations. Over-tightening can potentially weaken or strip the threads.

During tire inflation, it’s recommended to place the wheel inside a safety cage (refer to image below) or use straps to secure it if a cage is unavailable. Use a long air hose to maintain a safe distance from the tire during inflation. Use a dump valve equipped with a pressure gauge that is capable of quickly deflating the tire in case of an emergency. Never exceed the maximum cold pressure recommended by the tire manufacturer.

Split rim cage example

(image courtesy of www.thevettebarn.com)

Some wheel assemblies can only be inflated to the maximum cold pressure when secured to the vehicle; this information should be available in your manufacturer manuals. If this is the case, inflate the tyre to about 30 kPa or 5 psi, then bolt the wheel to the hub of the vehicle and locate the vehicle in an appropriate area before inflating to full pressure; ensure the operator is outside of the potential projection area.

Further information

There are many sources of further information on split rims, including:

- Safe Work Australia – Split rims and compressed air guidance material

- Australian Standard 4457.1–2007 Earthmoving machinery – Off the road wheels, rim and tyres – Maintenance and repair – Wheel assemblies and rim assemblies

- WorkSafe NSW video on the dangers of split rims

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

By Founder, Paul Dean

Originally published September 2022

Updated July 2024

About the Author

Paul Dean is the Founder of Ideagen Plant Assessor. Paul spent 10 years working in the construction industry, and 5 years in the machinery supply industry where he developed a deep knowledge about mobile plant and machinery compliance. Paul's idea for Plant Assessor was created in 2004 after working in the motor vehicle and machinery auction industry and realising the complexity and lack of standardisation when managing machinery and equipment compliance. Read More.

Ready to find out more?

See what Plant Assessor can do for your business with a demo.