Inspecting Tyre Condition

Tyres are used on a wide variety of vehicles and machinery and their condition is often overlooked. Tyre condition is a crucial safety component for any wheeled equipment.

Tyres are the only contact your vehicle or machinery has with the surface it is operating on, making them one of the most important safety features of any vehicle or machine. Tyres need to respond accurately to steering commands, they need to roll smoothly and cope with the stresses that come from braking, cornering and accelerating. Above all, tyres need to keep vehicles safely and securely on the operating surface in different conditions including when dry, wet and slippery, or covered in snow and ice.

Tyres should be inspected regularly as part of a proactive maintenance regime, and must be part of any daily pre-start checklist. Here are some important considerations when inspecting tyre condition.

Tyre pressure

It is important to keep the right amount of air pressure in your tyres, including your spare. Correct pressure helps to ensure optimum braking performance and minimisation of wear. Correct pressures also optimise comfort, handling and fuel economy.

Under or over inflation reduces a tyre's ability to grip properly, which most importantly impacts upon braking capability. This will not only cause uneven tread wear but it has a substantial influence on handling. If the inflation is not adequate for the load being carried, the tyre temperature increases due to flexing, and excessive temperature can result in structural damage to the tyre. Tyres must be inflated to the pressure recommended by the manufacturer, and checked on a regular basis when the tyres are cold.

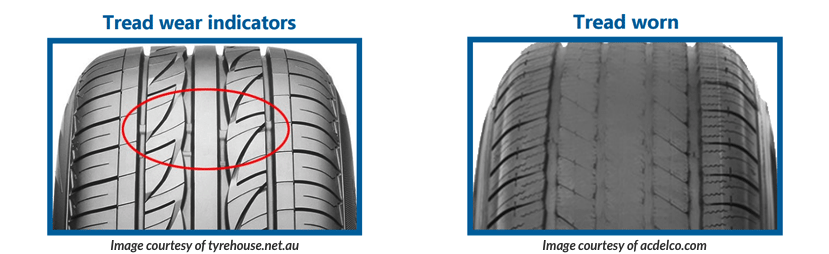

Tread wear

Tread wear issues can appear as flat spots or areas of rapid wear on the tyre. Tread wear issues are commonly caused from brake problems, suspension or alignment problems, an unbalanced tyre and wheel assembly or from misuse.

Tyres include tread wear indicators, and these are important tools for judging remaining tread depth. These are raised bars in the main longitudinal tread grooves, distributed evenly around the circumference of the tyre, which become level with the rest of the tread pattern once the minimum tread depth is reached. If uneven tyre wear is identified, and the minimum depth has not been reached, tyre rotation is a practical option to reduce the risk and increase the useful life of a tyre.

If the minimum tread depth has been reached, the tyre must be replaced. Any damage such as exposed wire, gashes in the tread, or smoothness and the tyre must be replaced. Smoothness is only acceptable on solid tyres only.itted on some self-propelled elevated work platforms.

Sidewall damage

It is important to inspect the sidewalls of tyres, which includes both external and internal sidewalls. Inspectors must ensure that they make the effort to inspect internal sidewalls when inspecting tyre condition.

Sidewall damage can appear as cuts, tears, bubbles or scrapes anywhere along the sidewall of the tyre. This type of damage commonly occurs when a tyre encounters an unexpected hazard, which can include anything from rocks and curbs to pieces of metal.

Sharp objects or very concentrated stress usually cause cuts and tears. Bubbles and scrapes occur due to impact damage or prolonged abrasion. Any sidewall damage should be inspected regularly and a judgement needs to be made regarding the need to replace a tyre. Tyre suppliers are able to assist in making judgements regarding the extent of damage and whether a tyre should be replaced.

Tyre separations

Tyre separations can appear as bulges on the shoulder of a tread face, or as a localised wear above the separated area. A groove worn along the shoulder could be a sign of separation. Separations are mainly caused by excessive heat during prolonged high speed driving, overloaded or under inflated tyre pressures. If tyre separation is visible, the tyre must be replaced.

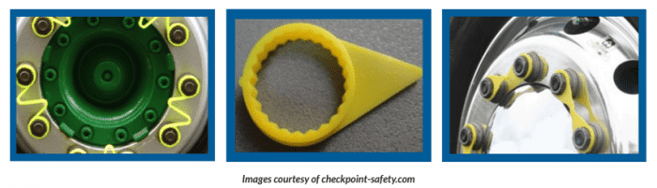

Wheel nuts

Wheel nuts must be checked regularly as part of a routine for inspecting tyre condition, to ensure they are tightened to the correct torque. Improperly torqued nuts or bolts can result in wheel assemblies coming off, brake damage, as well as broken and/or stripped nuts, bolts and studs. There are many different wheel nut indicator systems available that identify when a nut is loose or damaged. Torque settings should be as per the manufacturer’s guidelines.

How does Plant Assessor help with inspection of tyres

Plant Assessor risk assessments and pre-start checks include specific questions in relation to inspecting tyre condition. Assessors need to answer these questions, capturing suitable comments and photos in the event that a deficiency needs to further identified, examined and rectified.

As usual, when conducting an inspection, assessors should err on the side of caution, and when unsure, answer no to the question, which will flag the issue for further investigation. Assessors need to follow their usual lock out/tag out procedures if any significant deficiency is identified during an inspection. Plant Assessor reports, which are immediately available following completion of an assessment, contain comprehensive risk ratings to assist in making a decision on whether or not to tag out a piece of equipment.

In summary, when inspecting tyre condition, assessors need to consider the following important aspects:

-

Tyre pressure

-

Tread wear

-

Any damage to the tyre

-

Any damage to the wheel or components

-

Wheel nuts are securely fastened

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ready to find out more?

See what Plant Assessor can do for your business with a demo.