Chainsaw safety

In this article

How to prevent chainsaw injuries

Common chainsaw usage

Chainsaws are more accessible than ever, with a wide variety available for users catering to needs and skill levels. Electric chainsaws can be purchased for as little as $99 and even more powerful petrol driven models from just $100 more. This increased accessibility means that virtually anyone can obtain a chainsaw, from professionals in forestry and logging, landscapers and emergency services, to those less educated such as homeowners and handy men.

As there is no permit and no training required to use chainsaws and operation of one looks relatively simple, many users will assume they will be fine to take on jobs themselves instead of hiring professionals. This ease of access undervalues the importance of proper training on chainsaw use and safety and often leads to serious injuries. Onus is on the user to ensure they are aware of the risks and know how to operate a chainsaw.

Chainsaw injuries

Each year, almost 1,000 Australians are badly injured while using a chainsaw. The majority of these chainsaw injuries occur around the home but there is still an alarmingly high number of work-based incidents as well.

STIHL Australia, one of Australia's most trusted chainsaw brands, recently launched its inaugural 'Chainsaw Safety Week' in 2024 (held held from 3–9 June), to help build awareness to chainsaw safety. STIHL donated $10,000 worth of brand-new MSA211 chainsaws to 22 Victorian SES units, which comes after SES services received more than 660 requests for assistance over ‘tree down’ emergencies in FY24 alone, highlighting how commonly chainsaws are used.

Over in the US, a 1989 study by the Davis-Garvin Insurance Agency, a specialist logging insurance underwriter, provided the crazy statistic that the average chainsaw injury requires 110 stitches and incurred medical costs of $5,600 on average.

A further comprehensive US study on chainsaw injuries undertaken between 2009 and 2013 reported a total of 115,895 hospital visits stemming from chainsaw use over this period. Most injuries were to males (95%) who were predominantly aged between 30-59 years. The majority of injuries were lacerations (80%) and the most common injuries were to legs and knees (36%) and left hand and wrist (35%).

The most common chainsaw injuries are:

-

Cutting injuries from kick back, pull in or when sharpening the chain

-

Crush and stick injuries from cut foliage or falling branches

-

Striking injuries, specifically eye injuries, from flying debris and sawdust

What causes chainsaw injuries

There is definitely insufficient planning and a lack of suitable risk controls in place when accidents such as the above occur. A closer look into this reveals that there are generally three contributing factors:

-

The design of the chainsaw

-

Safe operating procedures (SOPs)

-

Personal protective equipment (PPE)

1. Safe chainsaw design

Injury associated with the design of chainsaws has been significantly reduced thanks to the adherence of manufacturers to design standards such as AS 2726.1-2004 (Chainsaws - Safety requirements chainsaws for general use).

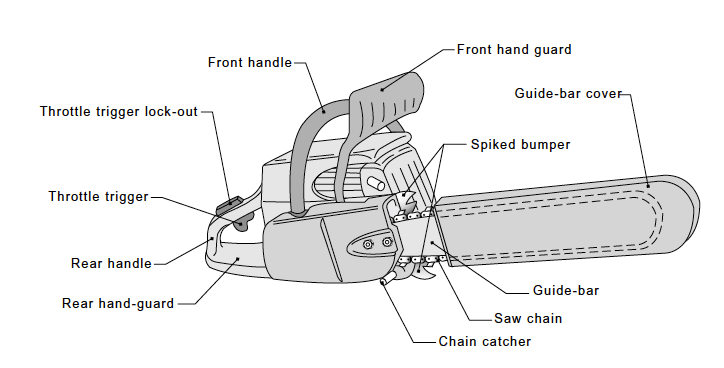

Design requirements that have improved chainsaw safety include such things as an automatic chain brake to prevent kickback, addition of a chain catcher, stricter vibration standards, throttle trigger lock-out and guarding of all rotating parts excluding the chain.

Periodic inspection of your chainsaw against mandatory and recommended safety features is recommended and something we help our clients with every day.

Below is an illustration identifying the components of a typical chainsaw.

2. Safe operating procedures (SOPs)

Controls around the way a chainsaw is used and by whom is critical to minimising risk and is determined by guidance from AS 2727-1997 (Chainsaws – Guide to safe working practices).

Some chainsaw hazards an operator must consider include:

-

Do they have the necessary training and physical capabilities to do the work?

-

Do they need assistance from other people or any additional special equipment?

-

Are they tired, fatigued or under the influence of alcohol or medication?

-

What are the current and predicted weather conditions? Extreme temperatures, heavy rain, lightning or strong winds can make chainsaw operation risky.

-

Are there any physical ground hazards such as undergrowth, stumps, holes etc that might hinder movement?

-

Are there any unsafe trees nearby? Look up! Are there any hanging dead or broken limbs overhead known as ‘widow makers’ for obvious reasons)

-

Who else is in the area? Be aware of other activity, traffic or machinery movements

-

What are your workmates doing? Is there sufficient separation distance between the chainsaw operator and other personnel? Do not work alone and maintain regular contact with other workers

-

Is there other tree felling activity in the area? Ensure a minimum of at least two tree lengths of any tree felling activity

3. Personal protective equipment (PPE)

PPE that should be considered minimum standard to potentially reduce the severity of chainsaw injuries includes:

-

Hearing protection

-

Eye protection

-

Foot protection

-

Long sleeves & trousers

-

Protective chaps

-

Hand protection

-

Sunscreen (where applicable)

How to prevent chainsaw injuries

Here are a few tips to make sure you are safe when operating a chainsaw, if you haven't got a professional to guide you. Always get advice if needed:

- Wear proper PPE. This includes head, hearing protections and safety glasses, gloves, cut-resistant chaps or chainsaw pants, steel-cap boots, plus a face shield if necessary to shield from debris

- Check your chainsaw before you start the job. Make sure it is in working order, there's tension and sharpness, bar condition, the state of the throttle and safety features are functioning properly and that all nuts and bolts are secure

- Work area check. Take a look at your work area and make sure there are no objects in the way of the tree you are felling; create a clearance area of about two tree lengths of the area for people and animals. If people are around, make sure communication is clear and possible if needed, also making sure bystanders are outside the clearance area. Check your area will be well ventilated and you won't be overcome with exhaust fumes

- Chainsaw operation. Two hands should always be on the chainsaw. Have a steady stance with your feet shoulder width apart; make sure you are ready for the initial cut and possible kickback, as well as when cutting through the material. Don't operate a chainsaw when you are tired or fatigued and take breaks regularly on large jobs

- Be very aware of chainsaw kickback. When initially cutting into an object, there is the possibility of a kickback from touching the object and if it is closing in and pinching the saw chain. To reduce this, never use the nose of the chainsaw (top of the tip) and be aware of where the tip is at all times. There are reduced-kickback chains available if you are unsure about this. Take note of how the chainsaw reacts when cutting with certain parts of the saw, pull-in and pushback can happen when in contact

- Don't cut over shoulder height. This will increase the chance of kickback and can be very dangerous. Always make sure you have two feet firmly on the ground. If you are felling a tree which is at a taller height, look for the attachments available such as a pole pruner so you can still have your feet firmly on the ground. Always call in a professional when you are unsure about how best to do the job

- Finishing the job. Make sure the chainsaw has stopped before moving or putting it down. To prevent injury, release the trigger and utilise the chain brake after the chain has stopped rotating

- Always read the owners manual. Chainsaws can differ in size, safety precautions and cutting techniques. Always read the owners manual to ensure you are across this information before use

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

By Founder, Paul Dean

Originally published September 2022

Updated July 2024

About the Author

Paul Dean is the Founder of Ideagen Plant Assessor. Paul spent 10 years working in the construction industry, and 5 years in the machinery supply industry where he developed a deep knowledge about mobile plant and machinery compliance. Paul's idea for Plant Assessor was created in 2004 after working in the motor vehicle and machinery auction industry and realising the complexity and lack of standardisation when managing machinery and equipment compliance. Read More.