Hydraulic Hose Safety

Hydraulics are used on a wide variety of machinery, from pedestrian operated machines to large earthmoving and other equipment.

Hydraulic system components run at significant pressures and temperatures. Hydraulics pose hazards associated with heat and stored hydraulic energy, as well as crush hazards such as falling loads where hydraulic systems fail.

This guide is focused on inspecting for hydraulic hose safety using Plant Assessor.

Guidance material available in Australia and around the world has steadily been moving away from prescriptive requirements such as how to fasten, shield and safe distances from operators.

The current Australian Standard for Safety of Machinery has the following guidance – AS4024.1201:2014 clause 6.2.10 Pneumatic and hydraulic hazards Pneumatic and hydraulic equipment of machinery shall be designed so that – No hazardous fluid jet or sudden hazardous movement of the hose (whiplash) results from leakage or component failures.

Safe Work Australia specifically include high pressure fluid in the hazards checklist in the “Managing Risks of Plant in the Work Place Code of Practice”.

The major potential risks posed by hydraulics

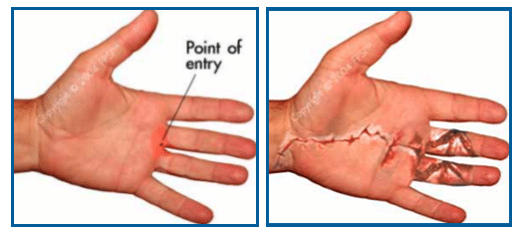

1. Injection injury

Injection injuries occur when a jet of hydraulic fluid pierces the skin and enters the blood stream. This generally occurs at close range and requires the fluid in question to be under pressure.

Injection injuries are a potential hazard on machines where the hydraulic hoses run in close proximity to the operator, such as on a vehicle-loading crane. It should be noted that injection injuries can often result in amputation of the injured body part, so extreme care must be exercised.

The following link, courtesy of SafeQuarry.com is a toolbox talk template on hydraulic injection injuries. Click here to view article

2. Burns

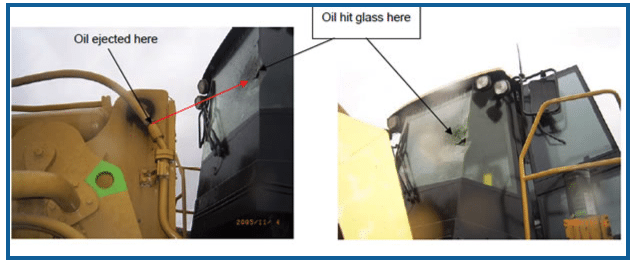

A hose burst resulting in the release of hydraulic fluid may cause burns to both operators and bystanders in the immediate vicinity. Containing a fluid burst is especially important in these situations. When assessing the risk, the proximity of operators, as well as bystanders should always be considered.

3. Whiplash/striking

Whiplash occurs when an unrestrained hose fails and the hose moves rapidly (whips) back and forth until the hydraulic energy is fully released. The whipping hose not only increases the likelihood of contact with hot hydraulic fluid but the hose itself can also cause striking injuries, including concussions, lacerations and broken bones.

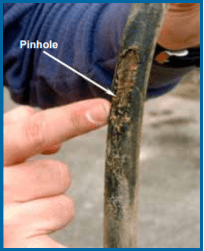

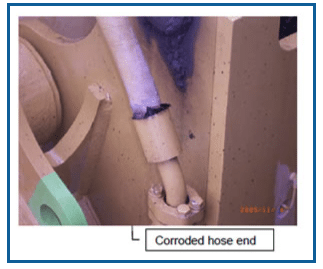

The most common point for failure in a hydraulic hose is at the fittings, where corrosion and stress related damage is most likely to occur.

The following link, courtesy of the NSW Mines Safety Regulator, depicts failure of a corroded hydraulic fitting, and how much force hydraulic fluid can exert during a hose burst. Click here to view article

How does Plant Assessor help with inspection of hydraulic hoses?

Plant Assessor includes the following questions for any item of plant that has hydraulics –

-

“Does this item of plant have hydraulic hoses?”

-

“Are all hydraulic hoses and fittings free from damage and protected from damage at all points where the hoses come into contact with the plant structure? (if you answer no to this question document the location of the damage/contact in the assessor comments section)”

-

“Are all hydraulic hoses and fittings located or shielded to protect the operator from injury due to fluid jet or movement (whiplash) of the hose as a result of leakage or component failure? (Diffusion sleeving can act as a shield but must be attached to the fitting not the hose)”

Assessors need to answer these questions Yes or No, and capture suitable comments and photos in the event that a deficiency needs to be further identified, examined and rectified.

Question 1 is straight forward; the item of plant either does or does not have hydraulic hoses. There is no remedial action required if the answer is No, and questions 2 and 3 can be answered N/A.

When answering Question 2 the assessor needs to consider the following:

-

The age of the hoses

-

Condition of the hose fittings

-

Rub marks in the paint work on the machine from hose contact

-

Wear to the external rubber coating and exposed steel braiding

-

Presence of shielding, sheathing or protection such as steel springs

-

The existence of hydraulic leaks

As usual, when conducting an inspection, particularly in relation to hydraulic hose safety, assessors should err on the side of caution, and where warranted take and upload photos and make relevant comments which will attach to the question in the risk assessment report.

When answering Question 3 the assessor needs to consider the following:

-

The location of the operator and bystanders during normal operation

-

The distance between hose fixings (including hose fittings) to determine how far the hose can whiplash if a catastrophic failure occurs. This will give an indication as to the minimum distance at which the operator or bystanders are at risk of a whiplash injury

-

The presence of shielding and sheathing

-

The presence of restraining clamps

Hydraulic hose safety is an important facet of the plant risk assessment process.

At Plant Assessor, we are focused on helping people take control of their machinery safety, and are only too happy to help you consider how best to manage risks associated with hydraulics and any other aspects of your machinery. Contact us today.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ready to find out more?

See what Plant Assessor can do for your business with a demo.