1 min read

Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

1 min read

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start...

.png?width=1920&height=1080&name=MKT-1015%20Article%20-%20How%20much%20are%20paper%20pre%20starts%20really%20costing%20you_%20(Image_%20Paper%20Pre%20Start).png)

3 min read

Many businesses operating machinery still rely on traditional paper pre start books for daily...

2 min read

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident...

3 min read

Pre start processes for machinery are crucial in ensuring operational readiness and machine safety.

2 min read

Fleet management is a highly important role for companies with operations that depend heavily on...

3 min read

Asset management can be a difficult, tedious and time consuming job. But it’s a critical component...

3 min read

Construction companies have been warned about a new crackdown on non-compliance when it comes to...

2 min read

Here at Ideagen Plant Assessor, we’ve previously spoken about people in the industry who don’t...

5 min read

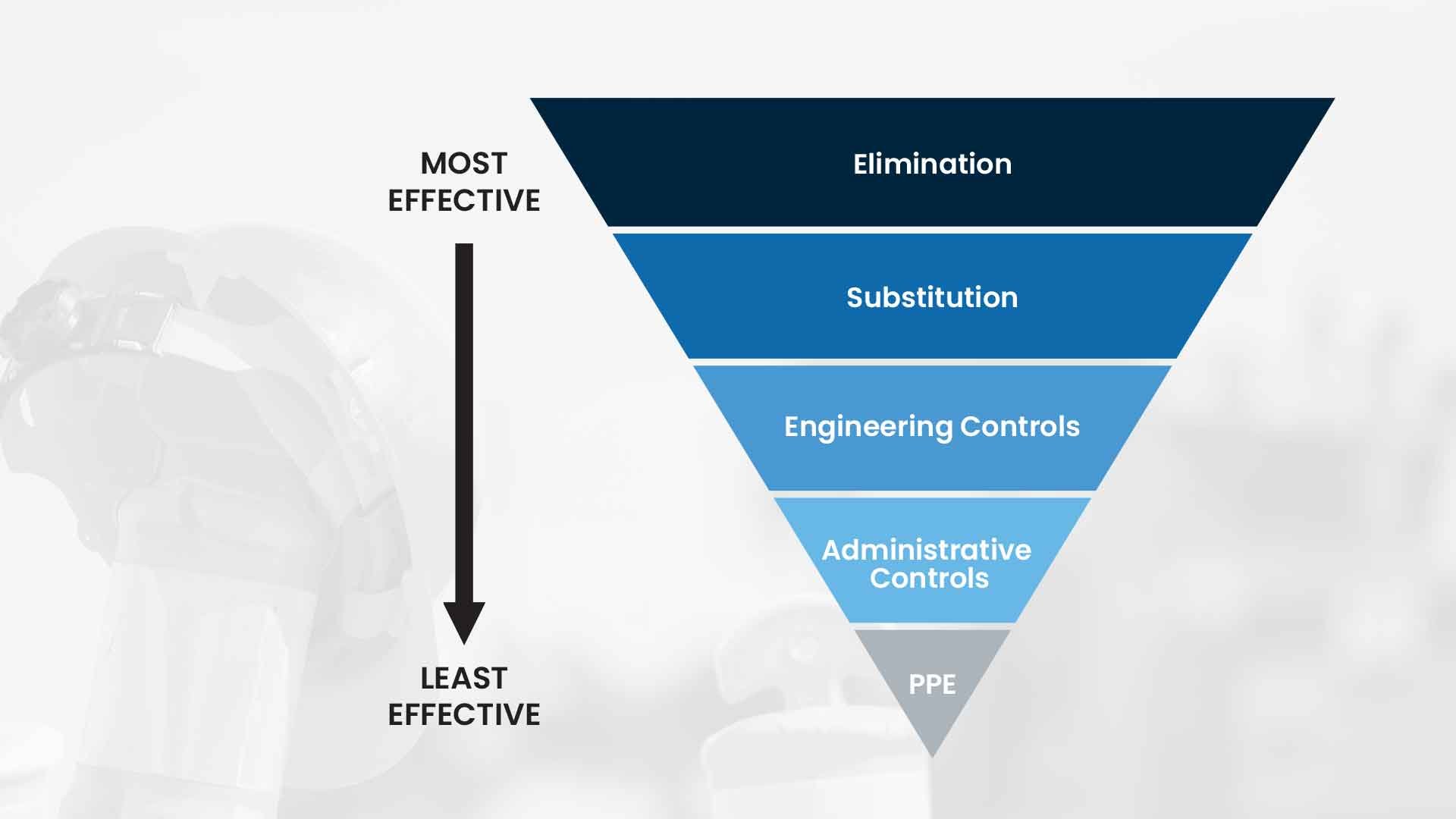

Application of the hierarchy of control is a mandatory requirement for duty holders in all...

3 min read

Here at Ideagen Plant Assessor we have been pioneers in utilising the power of technology to...

3 min read

If you are new to working with machinery, you may not have heard about digital pre starts. You...

.jpg?width=1600&height=899&name=clipboard%20(11).jpg)

3 min read

Without a doubt one of the most common questions we are asked at Ideagen Plant Assessor is – “why...