Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

Operator safety is arguably the most important part of any safe system of work for plant & equipment.

Given the nature of many of the inherent risks in construction, manufacturing and other higher risk industries, safe systems of work tend to end up with a heavy reliance upon administrative controls.

The reason administrative controls are considered a relatively weak method of risk treatment, is that they rely upon personnel being aware of the control(s) and voluntarily choosing to implement/follow them. The fundamental weakness is therefore the reliance upon operator competency, knowledge and discretion. For more information on this, see our article Hierarchy of control explained.

As a result of all of this, our experience tells us that a large proportion of plant & equipment related safety incidents can be attributed to what is considered “operator error”. Operator error can be split into two broad types:

Type 1: Genuine errors, such as a lapse in concentration leading to an excavator bucket hitting a truck cab.

Type 2: Lack of understanding of procedure and/or failure to follow procedure

There are those who would argue that there is no such thing as a Type 1 errors as everything we do should be covered by a procedure, meaning all errors will be type 2. To those people, I say, get with the program and stop dreaming – it is you who is making our workplaces too complex, drowning in paperwork, and hard to understand.

The frequency and consequence of both of these types of errors can be minimised.

If you look at it holistically, minimising errors and at risk behaviours is all about understanding and managing the knowledge and competency of the people working on your site.

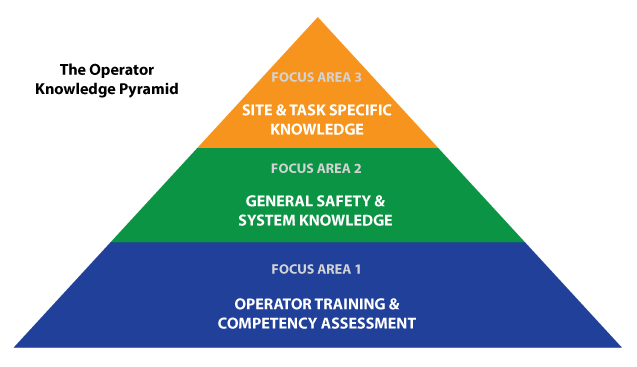

At Plant Assessor, we have developed this concept called the knowledge pyramid.

The knowledge pyramid tries to simplify the concept of competency and knowledge management into more manageable pieces.

The three focus areas are summarised below.

Focus Area 1: Plant operator training and competency

This is the most important – and onerous – of the three focus areas. It requires active, ongoing and active management to ensure your operators are competent.

The good news in the Vocational Education & Training system provides the framework for nationally-recognised training. The challenge is that there’s a very wide range of Registered Training Organisations with varying levels of experience and success so you need to do your homework when choosing as training partner. The RTO you select should:

Be capable and reliable, preferably with a good track record in the industry

Focus on your needs

Be able to provide the relevant units of competency and qualifications you require

Provide flexible training that fits with your business and the sector in which you operate

Please note that while it is not mandatory to use an RTO to train and determine competence of operators, nor is it mandatory to use the national VET framework, it is considered best practice. Also, High Risk Work Licences are only issued by State regulators following receipt of confirmation of competency issued by an authorised RTO.

Once you have found an RTO, you need to identify skills gaps for training and provide recognition of prior learning where appropriate. Tickets or certificates must also be issued as employees complete their training.

But the initial training is not where the assessment ends – you need to continually verify operator competency (especially in high risk work). After all, common sense will tell you that that unless a competency is used on a regular basis, it is likely to fade. That is not to mention the fact that changes in machine design and capability can affect the operator’s competency. Your RTO can help you set up a schedule of ongoing assessment and help you verify operator competencies.

Focus Area 2: General operator safety and system knowledge

Ongoing consultation with your staff and contractors is vital because it reinforces safety knowledge and increases employee engagement. It’s important to make sure that all your operators have been through relevant inductions, and have a thorough understanding of your safe systems of work and how to manage risks. General safety knowledge can be broken into two parts: initial induction and ongoing consultation.

As a new staff member joins your organisation or a new contractor is added to a job, it’s important to equip them with information in relation to your WHS Organisational Structure, WHS Consultation overview and mechanisms.

This should include the process for:

Hazard identification, machinery risk assessment, incident reporting and injury management

Emergency procedures

Site work WHS Management

In the construction industry, all workers need to receive “White Card” induction ensure a minimum level of general construction industry safety knowledge.

Under the harmonised WHS laws, PCBUs have to consult on issues such as:

Identifying hazards and assessing risks

Ways to remove or minimise risks

Procedures for fixing health or safety issues, monitoring the health of workers or workplace conditions, training, information and consultation with workers

Safe Work Australia has published a model Code of Practice on Work Health and Safety Legislation.

It’s good practice to “table and review” key safe work policies procedures regularly to ensure workers are aware of their contents, and to identify any gaps. This may be as simple as a regular item on your toolbox meeting agenda, or may more detailed consultation, depending on the issue.

Focus Area 3: Site and task specific procedures and knowledge

This is about your operators being aware of the risks and controls identified in the risk management plan. It involves inducting them in site-specific risks such as:

Traffic management

Incident reporting & management

First aid & emergency response

Alcohol & drugs

Plant & Equipment – site rules

PPE

High risk work-management principles

It is also important that they review, understand, and sign off on any SWMS related to any work they will be doing on site.

Operator training & knowledge management is a fundamental part of keeping your worksite safe, but it is also one of the hardest variables to manage. For more information, please contact us.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

.png)

Many businesses operating machinery still rely on traditional paper pre start books for daily machinery checks. While these booklets serve their...

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident involving a concrete pump resulted in a worker’s hand...