Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

1 min read

![]() Matt Ireland

:

Updated on January 24, 2025

Matt Ireland

:

Updated on January 24, 2025

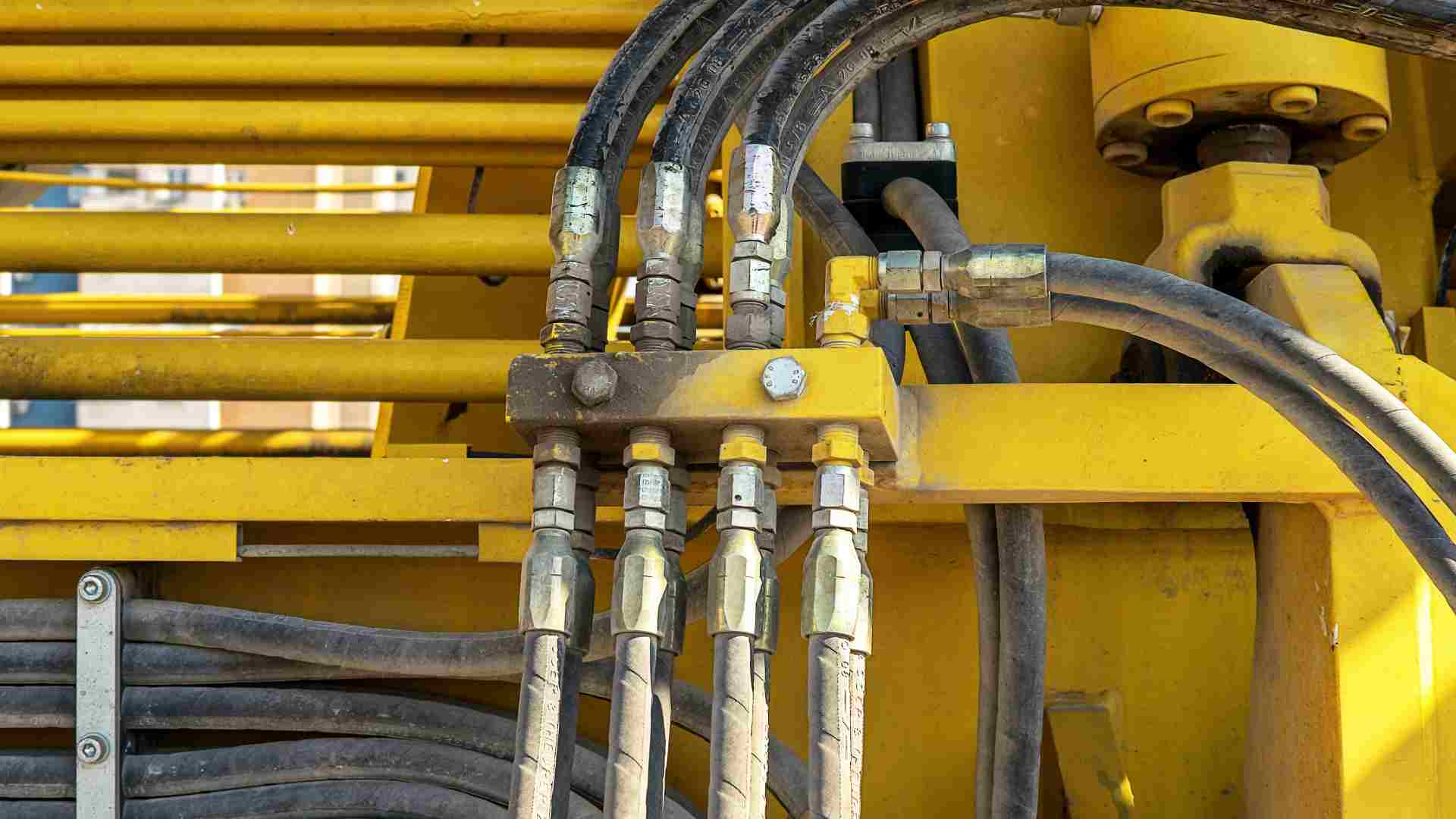

A hydraulic oil incident involving a continuous miner earlier this year is under investigation.

The operator was standing on the equipment’s platform in an underground coal mine in NSW, when hydraulic oil sprayed from the retraction hose. The fluid sprayed at the operator, who was only 800 to 900 millimetres away from the location of fluid release, at a pressure of 2000 psi.

No injuries have been reported.

The NSW Resources Regulator says the spiral wrap used to guard the hose did not adequately protect it from rubbing against the edge of a metal plate on the machine.

Incidents involving hydraulic fluid have the potential to cause serious injury to machinery operators and those in the vicinity. Some of the major risks that can be posed by hydraulic fluid include:

Injection injury: when fluid pierces the skin and enters the blood stream.

Burns: caused by hot fluid making contact with the skin.

Striking and whiplash: when the hydraulic hose contacts a person due to unrestrained movement.

As with many of the machinery incidents we see here at Ideagen Plant Assessor, this one could have been avoided. This highlights just how vital regular inspection of machinery is in preventing serious incidents.

Had thorough risk assessments and daily pre start checks been conducted on this continuous miner, the wear on the spiral wrap guarding would likely have been identified prior to the incident occurring. Corrective actions, such as repairing the hose and preventing future wear, could have been implemented, and the hazard could be closely monitored to avoid future incidents.

When risk assessing or inspecting hydraulic hoses, consider:

The age of the hoses

The condition of the hoses

Rub marks on a machine’s paint from hose contact

Wear on the hose’s external rubber coating

The existence of hydraulic leaks

Identifying these issues early can go a long way to promptly reducing the risk of hazards and mitigating the potential for incidents to occur.

For more information on hydraulic fluid safety around machinery, see our other articles and guides.

You can't hose down the importance of hydraulic safety

Managing machinery hazards related to hydraulic fluid doesn’t have to be difficult. Our team of experts is on hand to help! Contact us today by phoning 1300 728 852 or emailing info@assessor.com.au.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

.png)

Many businesses operating machinery still rely on traditional paper pre start books for daily machinery checks. While these booklets serve their...

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident involving a concrete pump resulted in a worker’s hand...