NSW Quick Hitch Position

NSW quick hitch position paper - revised November 2015

NSW released a revised position paper covering supply, installation and use of quick hitches. In early 2014 WorkCover NSW (now SafeWork NSW) released a position paper covering the supply, installation and use of semi-automatic quick hitches on excavators and backhoes. In June of that year, we published an explanatory article in our newsletter, which also outlined the initial stance of other Australian regulators on the NSW position paper. Recently, SafeWork released a revised position paper, expanding on and clarifying its position on the range of quick hitches available.

There are two key changes in this latest position paper:

-

The existing deadline on the supply and installation of semi automatic quick hitches remains 30 April 2014, however semi-automatic hitches installed before 30 April 2014 can only be used until 31 December 2022.

-

Fully automatic hitches that allow the attachment to swing if the primary retention device fails cannot be supplied or installed after 31 December 2015. Fully automatic hitches that allow swinging installed before 31 December 2015 can only be used until 31 December 2022.

Manual quick hitches and fully automatic quick hitches complying with AS4772 that do not allow the attachment to swing if the primary retention device fails can be supplied, installed and used as per the manufacturers instructions at anytime.

Plant Assessor assessment questions on machines that use quick hitches will be updated to apply these specific requirements on 1 January 2016.

Summary of SafeWork NSW’s revised position on quick hitches

| Type of hitch | Typical usage | SafeWork NSW position |

| Half hitch | Excavators up to 3 tonnes |

Allowed to supply |

| Mechanical hitch | Backhoes & excavators up to 5 tonnes |

Allowed to supply |

| Semi-automatic hitch | Backhoes & excavators 3 to 8 tonnes |

Allowed to supply until 30 April 2014. If installed prior to 30 April 2014, use is still permitted until 31 December 2022 |

| Automatic hitch - allows swinging | Larger machines however is also available for machines as small as 2.5 tonnes |

Allowed to supply until 31 December 2015. If installed prior to 31 December 2015, use is still permitted until 31 December 2022 |

| Automatic hitch - does not allow detaching or swinging | Machines over 2.5 tonnes | Allowed to supply |

How does Plant Assessor help you manage these requirements?

There are two steps required to answer the Plant Assessor questions regarding quick hitches:

Step 1 – Identify the type of hitch

| Type of hitch | Identification method |

| Half hitch (image 1) |

Has a jaw on one side of the hitch and a removable pin on the other. The pin must be inserted and removed manually. |

| Mechanical hitch (image 2) |

1. Requires manual effort to unlatch. Latching is achieved by manipulating the hitch and attachment so that the weight of the attachment applies pressure to the latching device to allow the pin of the attachment to move into the latched position. This type of hitch has a mechanical locking device such as a spring to prevent unlatching of the attachment. 2. Requires manual effort to latch and unlatch. This type of hitch has a mechanical locking device such as a pin to prevent unlatching of the attachment. Essentially this is a semi-automatic hitch without hydraulics. |

| Semi-automatic hitch (image 3) |

Attachment and detachment are achieved by a hydraulic ram engaging and disengaging a jaw. A manually applied mechanical locking device prevents the jaw from disengaging in the event of hydraulic failure or from being accidentally disengaged by the operator. The operator must get out of the cabin to install or remove the locking device. |

| Type of hitch | Identification method |

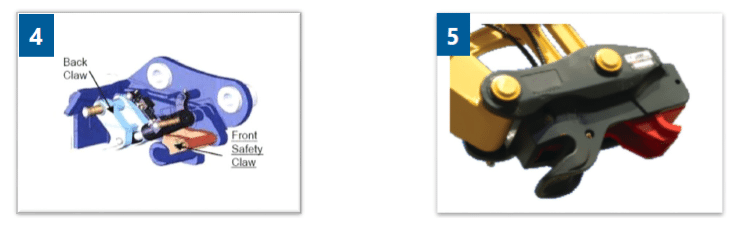

| Automatic hitch - allows swinging (image 4) |

A hydraulic powered a hitch that does not rely upon a manually applied mechanical locking device to prevent unlatching in the event of hydraulic failure or accidental operation. This type of hitch has a secondary locking device which prevents the attachment from unlatching from at least one side unless specifically actuated by the operator. This type of hitch is recognisable as they generally have a hydraulically operated moveable jaw on one side and a locking device on the other. |

| Automatic hitch - does not allow detaching or swinging |

A hydraulic powered hitch that does not rely upon a manually applied locking device to prevent unlatching in the event of hydraulic failure or accidental operation. This type of hitch has a secondary locking device which prevents |

Step 2 – Answer specific Plant Assessor quick hitch questions

Plant Assessor contains a number of specific questions for each type of hitch. Once the type of hitch has been identified, inspectors simply need to provide a yes or no answer to these clearly explained questions. Almost all of these questions can be answered via a visual inspection.

In relation to the last type (automatic hitch – does not allow detaching or swinging), a visual inspection may not allow an inspector to determine if the requirements of the Plant Assessor question for this type of hitch are fully met (i.e. has a primary and secondary locking device). An inspector may have to refer to the OEM to ensure the hitch satisfies these requirements.

By taking a structured and logical approach to the different requirements on these quick hitches, we help inspectors understand and manage compliance with what is a complex area of plant & equipment safety.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ready to find out more?

See what Plant Assessor can do for your business with a demo.