Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

When considering pressure vessels three questions jump to mind –

What is a pressure vessel?

Do I need to do anything special/extra if I have a pressure vessel?

If I answer yes to question the question above, what are the special/extra things that I need to do?

What is a pressure vessel? Luckily AS/NZS 1200:2000 Pressure equipment has a definition for us.

Pressure vessel—a vessel subject to internal or external pressure. It includes interconnected parts and components, valves, gauges and other fittings up to the first point of connection to connecting piping.

Simple enough. Vessels subject to internal pressure such as gas cylinders & air compressor receivers and those subject to external pressure such as vacuum tanks are all pressure vessels.

Do I need to do anything special/extra if I have a pressure vessel? Not all pressure vessels are subject to the requirements as defined in Australian Standards. Only vessels with a certain combination of pressure and diameter are required to comply with the requirements of the relevant Australian Standard.

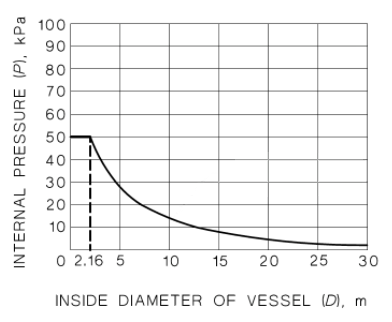

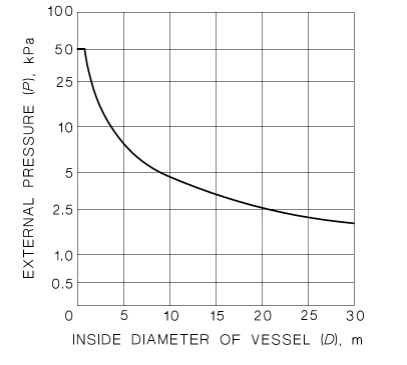

Here are the graphs that you can use to determine whether or not your vessel is subject to these requirements.

For vessels subject to internal pressure. Simply plot your pressure/diameter on the graph. If the point is above the line then your vessel is subject to the requirements of the relevant standard.

For vessels subject to external pressure. Simply plot your pressure/diameter on the graph. If the point is above the line then your vessel is subject to the requirements of the relevant standard.

Tips:

All vessels with a design pressure over 50 kPa are pressure vessels are subject to the requirements of the relevant Australian Standard.

If a manufacturer declares that there vessels are not pressure vessels because they don’t meet the definition as per SAE or ASTM don’t assume that their vessel is not subject to the relevant Australian Standard. SAE & ASTM are American standards.

Now that we have established that you have a pressure vessel subject to the requirements of the relevant Australian Standards, what are the requirements? The short answer is that pressure vessels will require –

A manufacturer’s plate with specific information marked upon it

A pressure gauge and

An inspection regime to be completed and documented.

There may be other requirements depending on the contents of the vessels and the hazard level of the vessel. The specifics of these requirements are included in Plant Assessor assessment surveys for the individual machines.

Please contact the team at Plant Assessor if you have any queries about pressure vessels or indeed any other technical queries.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

.png)

Many businesses operating machinery still rely on traditional paper pre start books for daily machinery checks. While these booklets serve their...

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident involving a concrete pump resulted in a worker’s hand...