Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

1 min read

![]() Ideagen Plant Assessor

:

Updated on April 19, 2023

Ideagen Plant Assessor

:

Updated on April 19, 2023

The Office of the Federal Safety Commissioner (OFSC) was set up in 2005 to foster excellence in work health and safety on Australian construction projects.

Whilst the accreditation scheme and its administrators have been subject to some criticism, it is fair to say that the OFSC has been the catalyst of a genuinely dramatic improvement in construction project safety since its inception.

To become accredited under the scheme, companies need to illustrate the existence and implementation of an exemplary safety management system. The OFSC has issued audit criteria and guidance to assist applicants understand what success looks like for these systems.

Anyone who has been through an OFSC audit will attest to the fact that they are rigorous, and that it is difficult to satisfy the audit criteria.

Plant Assessor responded early to the requirements of the OFSC and the scheme by enhancing its plant risk assessments and developing new functionality to meet difficult requirements relating to the management of sub-contractor plant.

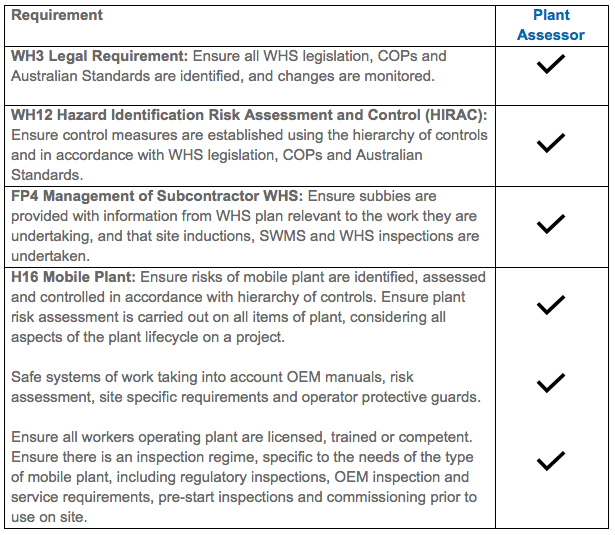

As a result of this, Plant Assessor is now being successfully used by many accredited entities to fly through the plant related requirements of an OFSC audit. The table below shows the relevant OFSC requirements that Plant Assessor meets.

Whilst it has required constant investment in development and intellectual property, we are delighted that our OFSC accredited clients are finding that Plant Assessor meets the plant centric requirements of OFSC audits so well.

Here at Plant Assessor we’re always keen to help people simplify and reduce the stress of managing plant professionally and diligently, so whether you are going through an OFSC audit, or just want to go digital and save time and money, please contact us to see how we can help.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

.png)

Many businesses operating machinery still rely on traditional paper pre start books for daily machinery checks. While these booklets serve their...

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident involving a concrete pump resulted in a worker’s hand...