Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

Our team at Plant Assessor regularly interact with our customers either onsite or on the phone with operators, mechanical staff, fleet managers and safety representatives. Often during these interactions we are asked about the need for safety labels.

I am the first to admit that at times it does seem that there are too many safety labels. This has been suggested to me on more than one occasion and every time I ask the same question, please let me know which labels are not required and I will remove them from Plant Assessor for your company. The problem is that if I remove a risk control, I need to replace it with an equal or better control, which may not be as acceptable.

Consideration of how we come to recommend a safety label may help answer this question for you.

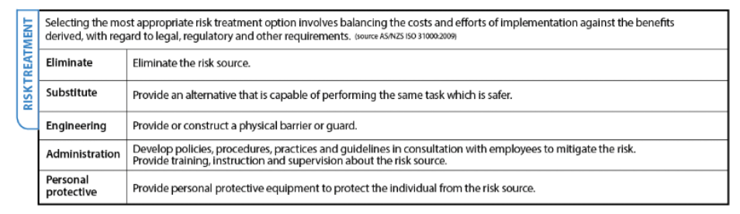

The risk assessment process is quite simple, identify the hazards, assess the risk and then control the risk. When controlling the risk we use the hierarchy of control as below.

If a hazard can not be eliminated, substituted or engineered out, as far as reasonably practicable then an administrative control or PPE are the last resorts.

There are many situations where this is the case when it comes to machinery. For example, every engine cover, bonnet or guard has moving parts under or behind them, if we were to follow the hierarchy of risk control above then every one of these would need an interlock to stop the moving part that the operator, maintenance staff and others are being guarded from as well as have a “time lock” feature that did not allow the guard to be opened until every moving parts had stopped, cooled etc. Is this practicable? Is it more practical to provide a guard with a label instead?

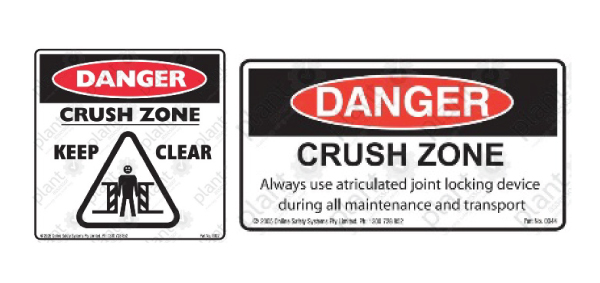

Another example is the crush zone created by the articulated joint on a wheel loader. Should this machine have a locking device fitted to the articulated joint which is automatically activated every time the machine stops and the operator opens the door with the engine running? Or should we have a manual locking device, a danger label and clear safety instruction label adjacent?

There are plenty of other examples where labelling is the most practicable solution to managing risk.

When talking about machines & safety labels another interesting consideration is that there is no specific Australian Standard for safety labels for machinery. There is an Australian standard for labels in general for the occupational environment, this is AS 1319:1994 – Safety Signs For The Occupational Environment. There is an International Standard for machinery ISO 9244:2008 – Earth-moving machinery – Machine safety labels – General principles. As such many machines that are imported into Australia have labels that are designed in accordance with this standard.

At Plant Assessor we are moving to align our safety labels with this standard.

If you have any comment regarding this I would love to hear them. Contact us by calling 1300 728 852.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

.png)

Many businesses operating machinery still rely on traditional paper pre start books for daily machinery checks. While these booklets serve their...

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident involving a concrete pump resulted in a worker’s hand...

.jpg)