Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

In our last newsletter we spoke about the four ‘pillars’ of Return on Investment (ROI) from investing in systematic management of machinery safety.

At the end of the day, regardless of site location, task, machine or operator, there are four key reasons why proactively managing machinery safety is crucial for anyone who owns, uses, sells or hires out plant & equipment.

1. AS 2359.1:2015 is currently in draft as DR AS 2359.1:2019

2. For the AS 2359 series of Standards, wherever practicable, the relevant International standards have been adopted. However parts 1, 2 & 12 continue to be locally developed, in the absence of suitable International Standards

3. The stability requirements for industrial trucks are now covered by AS 22915 series of standards previously AS ISO 22915

As far as the current draft DR AS 2359.1:2019 Powered industrial trucks General requirements is concerned the objective of the new standard is to set out additional requirements for the design, manufacture, marking and testing of industrial trucks not included in AS 2359.6:2013 Powered industrial trucks Self-propelled industrial trucks, other than driverless trucks, variable-reach trucks and burden-carrier trucks.

The major changes according to the committee are –

a. Addition of a definition for lateral stability

b. The increase in height from 800mm to 1500mm for ride on battery electric trucks with an elevated mast in clause 8.2.3 when fitted with lateral stability control

c. Updates of references for ISO adoptions

d. Deletion of clause 11.7 as this is now covered by AS 5144.3:2019 (still in draft)

e. Deletion of Appendix A as this is now covered by AS 22915.1:2018 &

f. Deletion of Appendix E as this is now covered by AS 5144.3:2019 (still in draft)

There are other changes that have been identified however there is little or no impact, for example, the overarching requirements for visibility that are defined in AS 2359.6:2013 clause 4.10.1 have been added to the draft standard as new clause 11.11.

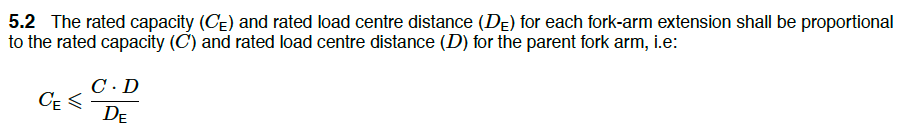

Another change that does have an impact is the addition of requirements for fork arm extensions (slippers) over and above AS 2359.15:2005. The new clause 6.4 is as follows.

6.4 Fork arm extensions (slipper forks) shall support 100% of the load that is intended to be lifted. The horizontal load centre distance shall be 50% of the length of the fork arm extension.

Fork arm extensions shall comply with AS2359.15:2005, clause 6.

Interesting stuff I know! What does that mean? The first requirement is quite straight forward, you must not lift anything with fork extensions that overhangs the extensions.

The second part is also quite straight forward but is a departure from the requirements of AS 2359.15:2003 in that the load centre distance used to be calculated by using a prescriptive formula, whereas now it is quite simply 50% of the length of the extension.

The formula was defined in clause 5.2 as follows –

This distance must be marked on the extension along with the rated capacity at that distance,

Once the draft standard is published we will let you know as well as make the necessary changes to Plant Assessor.

If you wish to read the draft standard for yourself please click on the following link –

https://infostore.saiglobal.com/en-au/Standards/DR-AS-2359-1-2019-1139968_SAIG_AS_AS_2699586/

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

.png)

Many businesses operating machinery still rely on traditional paper pre start books for daily machinery checks. While these booklets serve their...

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident involving a concrete pump resulted in a worker’s hand...