Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

1 min read

![]() Ideagen Plant Assessor

:

Updated on May 8, 2023

Ideagen Plant Assessor

:

Updated on May 8, 2023

If you were asked how’s your fleet looking, how would you respond?

I assume you would say, in what regard? As far as Plant Assessor goes we mean, all items are in PA, pre starts are being completed and recorded daily, machines are assessed, actions coming from assessments are completed or being managed, the next assessment is scheduled, service records are kept and all documents are in Plant Assessor and all this information is available at anytime to your operators or people you supply your machine to.

So how’s your fleet looking? If you reply “pretty good” then that’s great, if not, know that you are not on your own and that help is available to get everything on track quickly and cost effectively.

This is a question that we ask Plant Assessor users regularly to ensure that they are getting the most from not only the Plant Assessor software but also from the services that we offer. We have a team of professional assessors that are on hand to help you with every aspect of fleet management using Plant Assessor. These services include –

Getting your fleet into Plant Assessor accurately and quickly

Completing risk assessments thoroughly in line with your requirements including capturing machine hours

Adding photographs, documents, service records

Ensuring your assessment schedule meets your risk requirements

Managing actions arising from the assessment process including attaching safety labels

Ensure that all operators have access to Plant Assessor and know how to use the system to complete and share their daily pre start checks

Provide training for every aspect of the Plant Assessor software suite

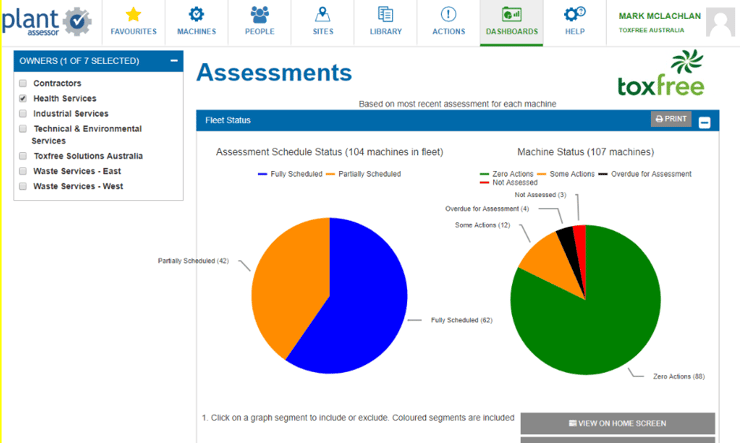

Below is an example of a well managed fleet through the Plant Assessor Assessment Dashboard – future assessments are scheduled & most actions are closed out.

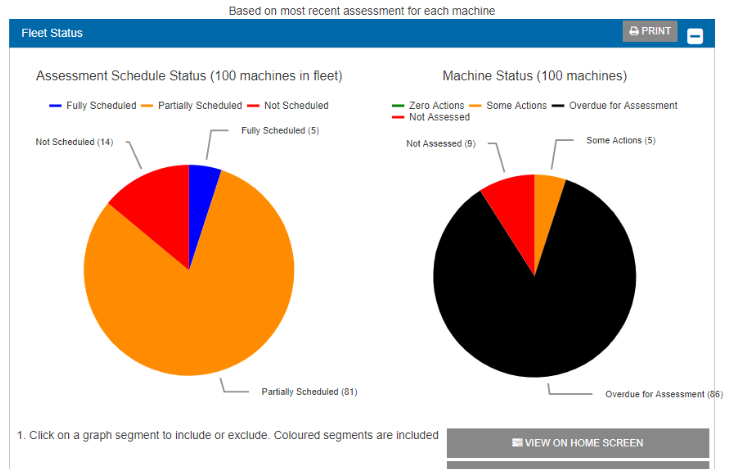

An example of a fleet that needs a little work – most machines have actions, have not been assessed, or are overdue to be assessed.

With a little help from the guys and gals at Plant Assessor you can be confident that your fleet is doing well.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

.png)

Many businesses operating machinery still rely on traditional paper pre start books for daily machinery checks. While these booklets serve their...

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident involving a concrete pump resulted in a worker’s hand...