Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

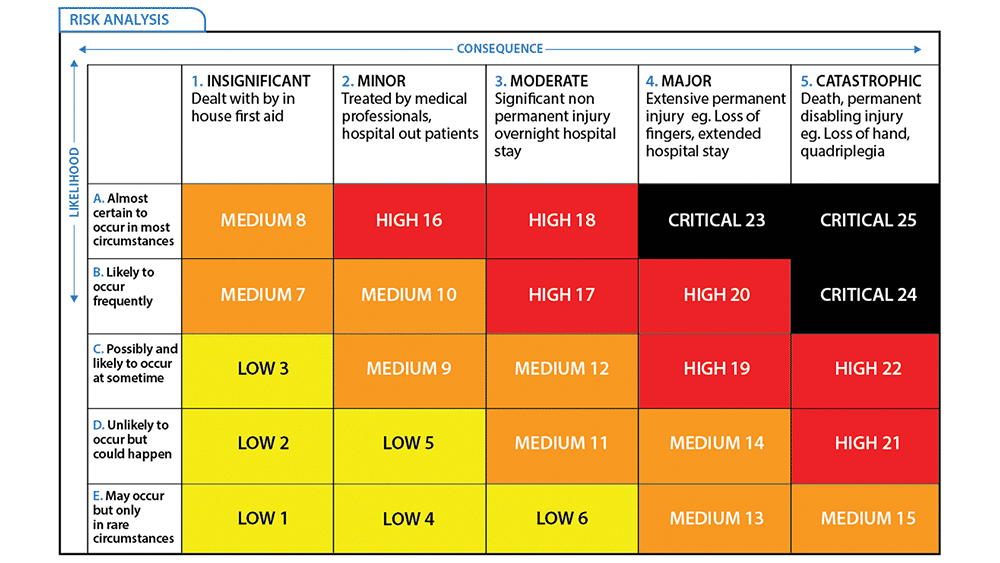

A risk assessment matrix allows you to best understand the level of risk you may be exposing yourself or others to. This method of rating risks is recommended by ISO31000 for assessing the risk to safety associated with machinery.

In this article:

What is a risk assessment matrix?

How does Ideagen Plant Assessor use the risk matrix?

Having said this, if you are unfamiliar with a risk matrix, they can be overwhelming and difficult to understand. That’s why we’ve written this article, talking all about how to read a risk matrix.

Firstly, let’s discuss exactly what a risk matrix is.

What is a risk assessment matrix?

A risk assessment matrix (or risk matrix) is a grid that visually represents risks that may occur in a particular situation. At Ideagen Plant Assessor, we use a 5×5 risk matrix, but you may also see a 3×3 or 4×4 risk matrix around. Each risk rating in the grid is allocated a number between 1 and 25 and is listed as low, medium, high or critical. Each risk rating is also colour-coded to signify the level of risk a hazard poses. Ideagen Plant Assessor’s risk matrix uses the colours yellow, orange, red and black, signifying low, medium, high and catastrophic risks respectively.

This matrix format is designed to determine the risk associated with an identified hazard and to convey the consequence and likelihood of risks identified in a risk assessment. Now that we know what a risk assessment matrix is, we can discuss how to read one.

3x3 risk matrix and 4x4 risk matrix examples

How to read a risk assessment matrix

You will notice on a risk matrix there are ratings along the top of the grid and ratings along the left-hand side of the grid. These are otherwise known as the x and y axes respectively. The x axis details the consequence a person could face if they encountered the hazard. They are ranked from left to right as such:

Insignificant

Minor

Moderate

Major

Catastrophic

The y axis outlines the likelihood of the risk occurring. They are ranked from top to bottom as such:

Almost certain to occur

Likely to occur frequently

Possibly and likely to occur

Unlikely to occur but could happen

May occur but rare

So, to read the risk matrix and determine the risk you may be facing, you need to determine the consequence of the risk and the likelihood of the risk occurring. Once you have these details, you can determine where the columns and rows from the X and Y axes meet and you’ll have your risk rating for the hazard you have identified.

How does Ideagen Plant Assessor use the risk matrix?

At Ideagen Plant Assessor, we use a risk matrix in our risk assessments to determine the level of risk each hazard that is identified could pose to you and your workers. This gives your assessors or people completing a Ideagen Plant Assessor machinery risk assessment a full understanding about the potential for an incident to occur once they have answered the question and read the risk management report.

The best part about the risk ratings provided to you in Ideagen Plant Assessor’s risk assessments is the way they are determined. Many risk ratings are subjective, as they rely on an individual’s judgement to determine the likelihood and consequence of a risk. This means that even though we could both be rating the same risk, you and I could both come up with very different risk ratings. But that’s not a problem here at Ideagen Plant Assessor, because our Machinery Compliance Engine (MCE) applies the decisions made by our risk assessment experts. The MCE will tell you the actual risk of a hazard when you complete your machinery risk assessment, ensuring there is no subjectivity in the determination of the risk rating, and avoiding any inconsistent or incorrect ratings.

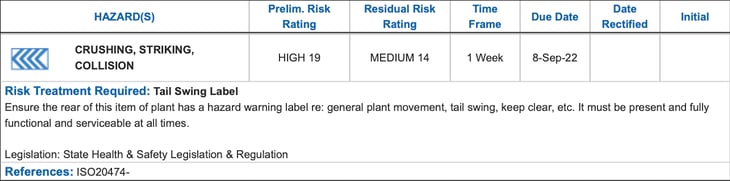

On that note, it’s also important to be aware of a mistake that we at Ideagen Plant Assessor have seen many people make over the years. When you implement a control and determine the residual risk rating of the hazard, it’s important to understand the consequence does not change in 99% of changes, only the likelihood. This is because controls generally can’t change the potential injury or fatality that may occur during an incident. For this reason in most cases, Ideagen Plant Assessor will only change the likelihood of a risk occurring, not the consequence, for a residual risk rating, providing you and your workers with an accurate risk rating.

You’ll also notice that the overall risk ratings from the matrix are included on Ideagen Plant Assessor’s safety labels, differentiating our labels from all others. This provides your workers with a greater understanding of the risks they face relating to the relevant hazard.

For example, in the below machinery risk assessment, one of the risk treatments for the presence of the hazard or crushing/striking/collision represented by the tail swing in a hydraulic excavator is the application of a tail swing area label on the item of machinery.

The preliminary risk rating is a High 19, and once the label is applied, the residual risk rating has been reduced to Medium 14. These labels are unique to Ideagen Plant Assessor. If you happen upon other safety labels with risk ratings, it is likely they breach copyright and are not rated correctly, so it’s best to have the original Ideagen Plant Assessor labels. To see more, head to our label store.

Do you need help assessing the risks associated with your machinery?

Our friendly team of machinery compliance experts can help you see why Ideagen Plant Assessor is the leading software for machinery risk assessments. To find out more or to request a demo, contact us today on 1300 728 852 or info@assessor.com.au.

Alternatively, you can learn more about reducing the issues associated with manual risk matrices by watching our on-demand webinar, Nail machinery risk analysis and mitigation with automation.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

About the Author

Paul Dean is the Founder of Ideagen Plant Assessor. Paul spent 10 years working in the construction industry, and 5 years in the machinery supply industry where he developed a deep knowledge about mobile plant and machinery compliance. Pauls idea for Plant Assessor was created in 2004 after working in the motor vehicle and machinery auction industry and realising the complexity and lack of standardisation when managing machinery and equipment compliance. Read More.

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

.png)

Many businesses operating machinery still rely on traditional paper pre start books for daily machinery checks. While these booklets serve their...

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident involving a concrete pump resulted in a worker’s hand...