Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

I think that it is fair to say that the future for motor vehicles is looking more and more electric. There are new electric vehicles hitting the road every day. The majority of the world’s car manufacturers seem to be either releasing their 1st electric car or the next version of their existing models.

These include the Tesla range, the Nissan Ariya, the BMW i7 and iX3, the Audi Q4 e-tron & Artemis, the Vauxhall Mokka-e, the MG 5 and the VW ID.4 to name a few. If these vehicles are the standard then the future looks very bright indeed, they are stylish, quiet, have low emissions and reputedly very reliable.

That’s all well and good for cars but what about trucks and machinery I hear you ask? It seems to me that trucks are already on the same path as cars and it is only a matter of time until electric trucks become the norm.

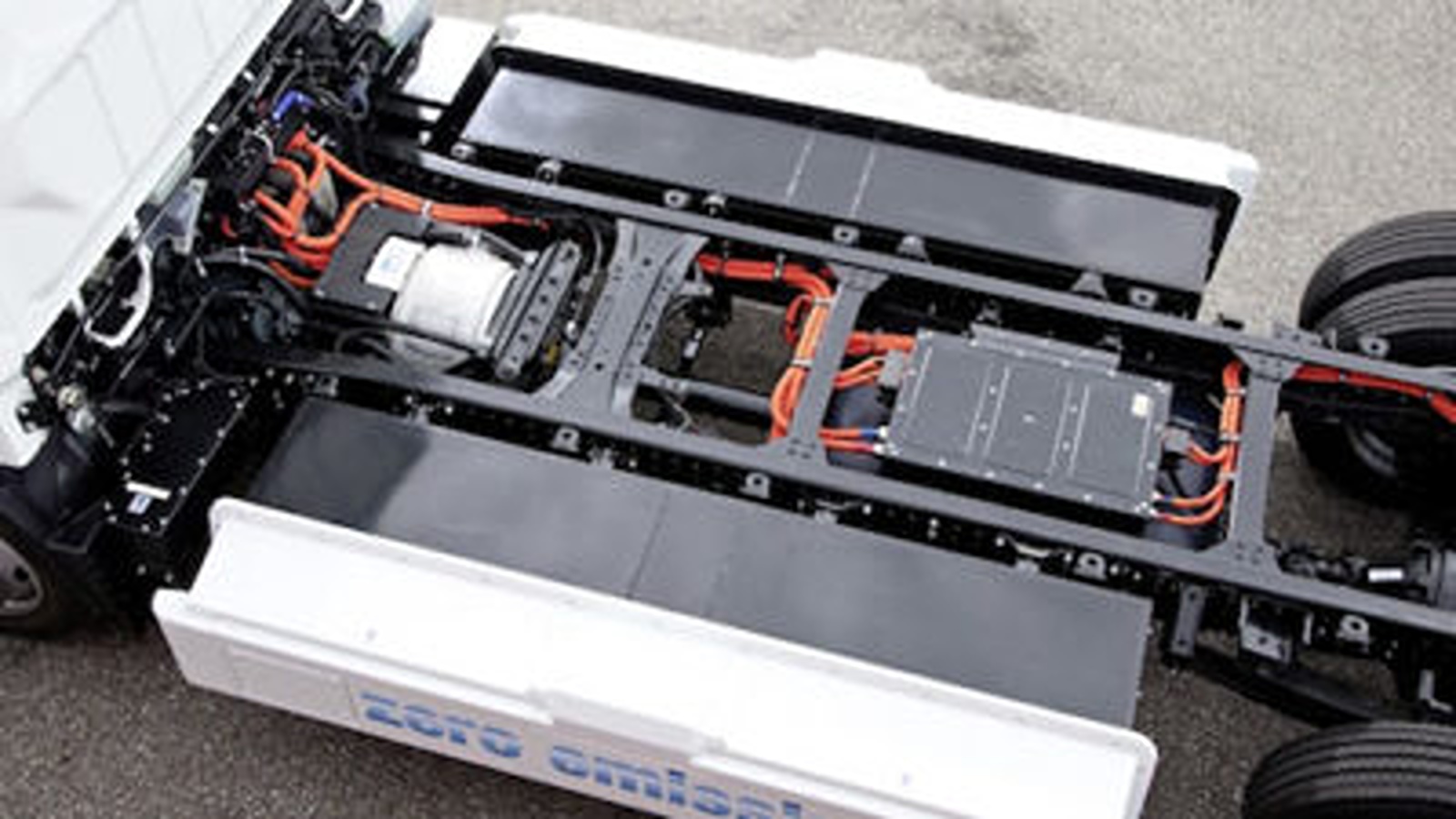

The Fuso eCanter is soon to be on the road in Australia and Isuzu already has concept models. SEA Electric is an Australian company building electric drive systems for commercial vehicles and trucks that can be retro fitted into existing vehicles. They have been fitting their system into vehicles for a little while now and these vehicles are hitting the road.

The reason that smaller trucks have been the first to move towards electric power is that like cars they have a daily opportunity when not being used to charge. Range is currently around 200 kms. It will be interesting to see what happens with larger long haul trucks. Hydrogen is definitely an option.

Just like trucks, smaller electric earthmoving machines are already being developed and sold. Larger electric machines such as draglines have been in use for a long time in the mining industry. All the major manufacturers seem to have electric models for sale now and if not then very soon.

Regardless of the power source for cars, trucks and machinery the safety requirements and the need to manage these requirements still remains.

The inclusion of the ISO 6469 Electrically Propelled Road Vehicles – Safety Specifications series of standards & AS 5732 Electric Vehicles Operations – Maintenance and Repair into Plant Assessor will be finalised for road going electric vehicles this month.

The requirements for these vehicles are more detailed and onerous than other battery powered equipment already in Plant Assessor such as lift trucks. These requirements include guarding, power indication, electric circuit protection, post crash performance, labelling and safety devices.

These requirements can vary depending on the voltage class of the vehicle as well. This is because of the additional hazards associated with the high voltage systems in electric power systems that are not present in conventional diesel powered road going vehicles.

We are finalising the following new type Truck – EWP boom – EV (electric vehicle) this month. Additional electric vehicles such as specific truck types and cars can be added upon request.

Plant Assessor is still the first choice to help manage these requirements regardless of the power source.

If you have any questions about this or any other articles please contact the friendly team at Plant Assessor on 1300 72 88 52.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

.png)

Many businesses operating machinery still rely on traditional paper pre start books for daily machinery checks. While these booklets serve their...

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident involving a concrete pump resulted in a worker’s hand...