Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

If the requirement to complete a machinery risk assessment is hard to get your head around, then the requirement to do it again and again on the same machine is surely even harder to comprehend.

To answer the question, 'how often do I need to conduct a risk assessment on machinery?' - perhaps we need to answer a couple of other questions first.

The answer to question 1 is reasonably straightforward, quite simply in Australia everyone involved in the supply and use of machines has a positive duty to identify and reduce the risk associated with machinery. This includes designers, manufacturers, importers, suppliers and users.

I could bore you with every single line of law that creates the requirement to complete a machinery risk assessment but I won’t. This detail is available on our website, click here to view links and explanations of the various laws across Australia.

In the interest of yours and my sanity let’s agree that for each of these people or businesses that have a duty, each state of Australia has a statement in their health and safety laws along the lines of – “The person with management or control of fixtures, fittings or plant at a workplace must ensure, so far as is reasonably practicable, that the fixtures, fittings and plant are without risks to the health and safety of any person”

Additionally there is specific information explaining how to do this in each state. The WHS Regulations which cover most of Australia have detailed information in clauses 34, 35 & 36. These define the duty to identify hazards, manage risks to health and safety and the hierarchy of risk control.

The answer to question 2, why do I need to reassess my machines, is in clauses 37 & 38. These define the requirement to maintain and review the control measures that are implemented as a result of the risk assessment process. Below are the important parts of each clause (click the title to see the full clauses):

37 Maintenance of control measures

A duty holder who implements a control measure to eliminate or minimise risks to health and safety must ensure that the control measure is, and is maintained so that it remains, effective, including by ensuring that the control measure is and remains:

(a) fit for purpose, and

(b) suitable for the nature and duration of the work, and

(c) installed, set up and used correctly.

38 Review of control measures

(1) A duty holder must review and as necessary revise control measures implemented under this Regulation so as to maintain, so far as is reasonably practicable, a work environment that is without risks to health or safety.

I hope this answers question 2.

That leaves us with the original question, how often do I need to conduct a risk assessment on machinery? The answer to this question is a little subjective as there is no definitive answer in the legislation or supporting guidance material.

The answer is, the frequency of reassessment needs to ensure that the duty created by the requirement that “fixtures, fittings and plant are without risks to the health and safety of any person” along with the specific requirements of clauses 37 & 38 of the WHS Regulations are met. It is subjective and depends on your appetite for risk.

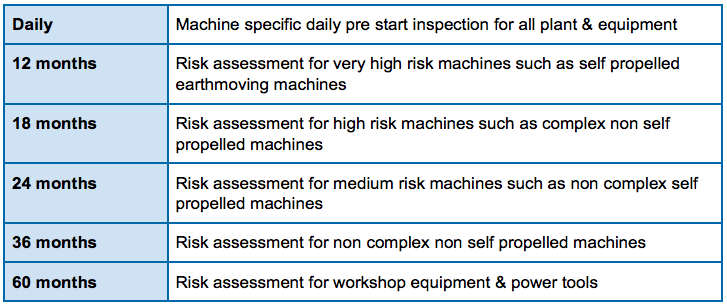

Plant Assessor does have built in recommended reassessment time frames which are based on a combination of the following factors:

Manufacturer’s maximum service intervals

Previous regulator’s codes of practice

The conditions & environments in which machines are used & assessed

Years of industry experience & consultation with industry experts

These inspections and time frames are as per the table below.

If you have any questions please contact us anytime by completing the form below or call us on 1300 728 852.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

.png)

Many businesses operating machinery still rely on traditional paper pre start books for daily machinery checks. While these booklets serve their...

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident involving a concrete pump resulted in a worker’s hand...