Pre Start Plus rebranded to Ideagen Asset Guard

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

|

|

Machinery Pre Starts

|

|

|

Risk Management &

|

|

|

Document Management

|

|

|

Dashboards & Reporting

|

|

|

Machinery Risk Assessments

|

|

|

Service & Maintenance

|

|

|

Safe Operating Procedures

|

|

|

MySite

|

|

|

View All Features |

Case Studies

Hear from our clients

Events

Find us at industry events

Guides

Find industry-specific guides

Learn

Educational content

News & Articles

Industry news and articles

Safety Legislation

We keep up with safety legislation

so you don't have to

Videos

Find overviews and informative

videos here

Webinars

View upcoming and on-demand webinars

Promotions

See our current promotions

FAQ

All of our frequently asked questions

Help Centre

How to use our software

View a Demo

Let us walk you through Ideagen Plant Assessor features

Release Centre

Product updates and release information

The short answer is, yes we are. The reason why is set out in the slightly less short answer below.

After a long time in the draft, comment and review phasesAS5327:2019 Earth-moving machinery – Access Systemswas released on the 29th of July 2019.

AS5327:2019 is as I mentioned in previous articles a modified version of ISO2867:2011 Earthmoving Machinery – Access Systems. My previous articles (see links below) have focused on the differences between the draft Australian standard and ISO2867:2011 as well as one other differences between ISO2867:2011 and ISO14122-3:2016 Permanent means of access to machinery – Stairs, stepladders and guardrails.

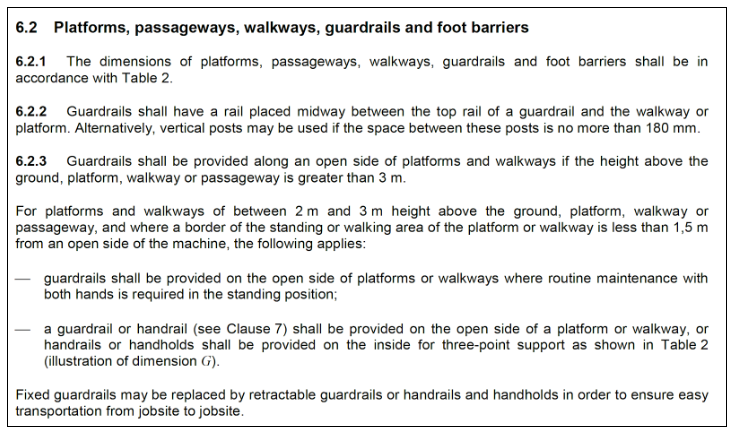

The main focus has been the height above the ground or nearest platform at which a platform requires a guardrail. The draft version of AS5327 required guardrails on platforms above 1m from the ground or nearest platform.

The newly published Australian Standard AS5327:2019 has changed to be in alignment with ISO2867:2011 by requiring a guardrail on platforms above 2 or 3m depending on the distance from the edge of the walkway/platform to the edge that you can fall from.

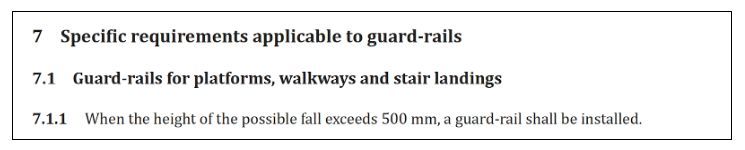

The 2 or 3m height is in stark contradiction to AS4024-1201:2014 General principles for design – Risk assessment and risk reduction which is identical to ISO14122-3:2016 Permanent means of access to machinery – Stairs, stepladders and guardrails which require a guardrail on any platform above 0.5m.

The relevant extracts from each standard are below.

AS5327:2019 & ISO2867:2011 state the following –

AS4024:2014 & ISO14122:2016 state the following –

WHS laws weigh in on the management of risk from falls as well. Regulation 78 & 79 of the WHS Regulations require that a person conducting a business or undertaking manage the risks to health and safety associated with a fall by a person from one level to another. These regulations talk about risks and suggest risk controls but do not specify the exact risk control.

It is important to note that Regulation 78 & 79 are laws where as all of the standards referenced are guidelines. Guidelines are there to help us determine what compliance could/should look like.

In summary there are 3 relevant pieces of information for consideration –

So the question then becomes – How do we reconcile these 3 pieces of information, particularly the obvious contradictions between the standards?

The answer lies in the risk assessment process. The risk assessment process has 4 steps –

1. Identify hazards

2. Assess the risk – consequence vs likelihood

3. Control the risk – hierarchy of risk controlPlant Assessor uses this process, in particular steps 2 & 3 to determine how to apply the available information from the various laws, standards, codes of practice and so on to each machine.

As a result of our interpretation of the available information and our application of the risk assessment process from August 26th 2019 onwards Plant Assessor will require all platforms above 0.5m from the ground or nearest platform on all machines that may have such a platform to have a guardrail unless certain criteria can be constantly maintained.

The new question will be –

Do all operator work platforms that are either –

a. above 0.5m and below 2.0m from the ground or nearest platform, where three points of contact cannot be constantly maintained by any person

on the platform performing expected tasks or

b. above 2.0m from the ground or nearest platform

have an approved handrail that meets the following requirements:

1. All handrails are at least 1.1m high(answer n/a if there are no platforms where the operator’s feet are above 0.5m & below 2.0m where a constant 3 points of contact is possible during access performing expected tasks)

The constant three points of contact requirement allows for operators checking fluid levels etc on machines such as motor graders where the operator’s feet may be in excess of 0.5 m above the ground, however three points of contact can be maintained because the operation is a single handed operation. An appropriate hazard warning label should be adjacent to advise that 3 points of contact is required in these areas.

Standards update table as of August 2019 –

Number

Name

DRAS5327

Earth-moving machinery. Access systems

AS3868

Earth-moving machinery, Design guide for access systems

Published

STATUS

29/07/2019

Current – modified version of ISO2867:2011

11/02/1991

Withdrawn 06/06/2019

AS4024.1100

Safety of machinery application guide

AS4024.1204

Safety of machinery – Electrical equipment of Machines – Part 1: General requirements

17/06/2019

Current – supersedes 2014 version

TBC

Current – revision of AS60204.1 2005 version

DRAS4024.1701

Human body measurements – Basic human body measurements for technological design

TBC

Current – revision of 2014 version

DRAS4024.1803

Safety distances and safety gaps – Minimum gaps to prevent crushing of parts of the human body

DRAS3000.Amd1

Electrical Installations

TBC

Current – revision of

2014 version

TBC

Current – revision of 2018 version

DRAS4852.1

Variable message signs. Fixed signs

TBC

Current – revision of 2009 version

DRAS4852.2

Variable message signs. Portable signs

TBC

Current – revision of 2009 version

DRAS5242

Cranes – Test code and procedures

TBC

Current – modified version of ISO4310:2009

As always, Plant Assessor customers can ask me a question regarding standards or legislative obligations anytime, simply email your question to support@assessor.com.au and they will be answered in this section of the newsletter each month.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ideagen Plant Assessor is pleased to announce the rebrand of its flagship pre-start app, Pre Start Plus, to Asset Guard. This rebrand aligns with...

.png)

Many businesses operating machinery still rely on traditional paper pre start books for daily machinery checks. While these booklets serve their...

A concrete company based in Melbourne has been convicted and fined $30,000 after an incident involving a concrete pump resulted in a worker’s hand...