Neutral Start Controls

The latest in our series of articles relating to common plant hazards and controls focuses on the hazards associated with uncontrolled movement of plant or vehicles, and the importance of neutral start controls.

Where there is a risk of uncontrolled movement at startup, a Plant Assessor inspection requires assessors to determine whether a neutral start control is in place.

Plant Assessor question

Does this item of plant have a working neutral start control fitted?

What machines have this question in the survey?

Plant Assessor asks this question on all mobile plant and complex fixed plant.

What is a “Neutral Start Control”?

A neutral start control is a risk treatment that ensures a machine is in a “neutral” condition during start up.

What are the potential hazards and the risk?

The potential hazards include collision, crushing, cutting, entanglement and striking. The risks associated with starting a piece of plant when not in the neutral condition are the potential for these hazards to cause harm or injury. For example, starting vehicles or mobile plant “in gear” will most likely result in plant lurching forward or backward, creating the risk of collision, striking or crushing injuries to bystanders or an operator starting the unit from ground level.

Legislation and regulator guidance

All States & Territories except Victoria & Western Australia

WHS Regulations 2011

| Regulation | Detail |

| 190 (1) (c) |

Designer of plant must ensure that the design provides for any operator controls for the plant to be located or guarded to prevent unintentional activation |

| 214 (c) |

The person with management or control of powered mobile plant must... manage risks to health and safety associated with the following... the plant colliding with any person or thing |

| 215 (4) |

The person must ensure that plant does not collide with pedestrians or other mobile plant |

Code of Practice (continued for all States & Territories except Victoria & Western Australia)

-

Managing Risks of Plant in the Workplace Code of Practice – Appendix B Hazard Checklist

-

Crushing – Can anyone be crushed due to uncontrolled or unexpected movement of the plant?

Victoria

Occupational Health & Safety Regulations 2007

| Regulation | Detail |

| 4.29 (k) (iii) |

Ensuring that the plant's operating controls are- located, guarded or of a double action type to prevent unintentional activation |

|

4.44 (6) (a) & (b) |

A person who, at a workplace at which there is any mobile plant, is an employer, the main contractor, a self-employed person, a person having control of the workplace or a person having access to the workplace must ensure in relation to each item of powered mobile plant that if there is any risk that the plant could collide with persons or any other plant or thing, then the risk is reduced as far as practicable. |

Western Australia

Occupational Safety & Health Regulations 1996

| Regulation | Detail |

| 3.5.26 (c) |

Designer of plant must ensure that the design provides for any operator controls for the plant to be located or guarded to prevent unintentional activation. |

|

3.5.34 (4) (a) & (b) |

An employer must ensure that the risk of powered mobile plant colliding with pedestrians or other powered mobile plant is eliminated so far as is reasonably practicable; or if it is not reasonably practicable to eliminate the risk, reduced so far as is reasonably practicable. |

Australian Standards

AS4024.1201: 2014 – General Principles for Design – Risk Assessment & Risk Reduction: Clause 6.2.11 Applying Inherently safe design measures to control systems

AS4024.1603-2006 Design of controls, interlocks and guards – Prevention of unexpected start up

What should I do if the plant or vehicle lacks a neutral start control?

There are a number of ways to ensure that plant is in a neutral configuration during start up. A competent mechanic or electrician will be able to install many of these easily.

| Machine type | Relevant hazards | Control type | Details |

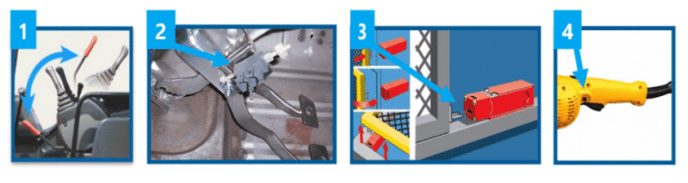

| Self-propelled (image 1) | Collision, crushing | Lever or gear mounted switch | A similar system can be fitted to direction a control, where moving the control lever or gear stick from neutral engages a switch that removes power to the starter. |

| Self-propelled (image 2) | Collision, crushing | Clutch mounted switch | A common method for achieving this condition on mobile plant (such as trucks) is through fitting a clutch-mounted switch wired to the starter relay. These switches are mounted in such a way that the clutch pedal must be fully depressed before the starter circuit is completed. Control methods such as these are already present on a number of later model trucks. |

| Fixed (image 3) | Cutting, crushing, striking, entanglement | Guarding interlocks | Many fixed machines have interlocks fitted to guards and controls that prevent start up unless all guards are fitted and/or controls are in the neutral position. |

| Hand held (image 4) | Cutting, striking, entanglement | Hold to run controls, dual action actuators | Most hand held machines have controls which require pressure to be activated as well as primary and secondary controls to enable operation e.g. a trigger that can only be operated once a button is pressed. |

Control efficacy

As with any risk treatment, the possibility that the treatment may be bypassed (unintentionally or deliberately) should be reduced as far as possible. Any device fitted must also be sturdy. A malfunctioning neutral start device is more likely to be bypassed and rendered ineffective therefore exposing the operator and bystanders to the original hazard.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information. Please contact us for further assistance.

Ready to find out more?

See what Plant Assessor can do for your business with a demo.