Split Rims

What is a split rim?

Split rims are wheel assemblies that are made up of a number of pieces held together by bolts or a lock ring, and are used on a broad range of plant including lift trucks, earthmoving machinery, trucks, buses and trailers. Split rims can be used with both pneumatic and solid tyres.

There are many hazards associated with tyre and wheel assemblies, and split rims pose substantial additional risks. The main additional hazard is the possibility of uncontrolled release of compressed air from the tyre, propelling components at high speed which can strike the operator and/or bystanders.

Every year people are killed or seriously injured when inflating a pneumatic tyre or removing a split rim assembly from a vehicle. During operation, all wheel and rim assemblies are subjected to loads and wear which can lead to fatigue of wheel components. This can lead to the development of cracks or other faults to the rim, if faults are left unattended, the rim/wheel can catastrophically fail. Owners and users of equipment fitted with split rims should inspect wheel and rim assemblies regularly, and any faults or damage found during an inspection marked and reported to the relevant personnel.

How to identify a split rim

Usually, split rims are bolted together so often there are two sets of bolts, one set is the wheel nuts that secure the wheel assembly to the hub, and the other set secures the split rims together.

Photo of split rim showing both sets of bolt holes

(image courtesy of www.weiku.com)

A typical split rim assembly

(image courtesy of SafeWork NSW)

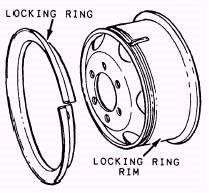

Another type of split rim has a bead that sits between the rim and the tyre. This is known as the lock ring and will have a gap in it (see images below).

Locking ring diagram

(image courtesy of www.tpub.com)

Locking ring

Removal and installation

Only trained and competent persons should remove and install split rims. Before handling split rims, you must ensure a safe work procedure is in place and also follow manufacturer's recommendations for removing a wheel, inspecting the tyre, disassembly and assembly of the rim and installation.

When working with pneumatic tyres on split rims, it is imperative that the tyre is deflated before loosening any of the fasteners to remove the split rim. If working on a vehicle with dual wheels, be sure to deflate both tyres, as the inner wheel may be damaged and be held together by the outer wheel. Once disassembled, all parts of the wheel assembly should be cleaned and inspected for cracks and deformation, corrosion and wear. Non-destructive testing may be required to detect cracks and faults in some components.

Inspect tyres for any defects before fitting on the rim and when securing the two halves of the rims ensure the torque is as per the manufacturers recommendations. Over tightening could lead to weakening or stripping the threads.

When inflating the tyre, it is recommended to place the wheel in a cage before inflating (see image below). If a cage is not available, use straps or other appropriate measures to restrain the wheel. Always use a long air hose so that the operator does not need to be too close to the tyre during inflation. A dump valve fitted with a pressure gauge, that is capable of rapidly deflating the tyre in the event of an emergency, should also be used. Do not inflate tyres beyond the maximum cold pressure recommended by the manufacturer.

Split rim cage example

(image courtesy of www.thevettebarn.com)

Some wheel assemblies can only be inflated to the maximum cold pressure when secured to the vehicle; this information should be available in your manufacturer manuals. If this is the case, inflate the tyre to about 30 kPa or 5 psi, then bolt the wheel to the hub of the vehicle and locate the vehicle in an appropriate area before inflating to full pressure, ensure the operator is outside of the potential projection area.

Further information

There are many sources of further information on split rims, including:

-

Safe Work Australia – Split rims and compressed air guidance material

-

Australian Standard 4457.1 – 2007 “Earthmoving machinery – off the road wheels, rim and tyres – Maintenance and repair – Wheel assemblies and rim assemblies.”

-

WorkSafe NSW video on the dangers of split rims

https://www.facebook.com/NSWSafeWork/videos/10155559349357112/

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information. Please contact us for further assistance.

Ready to find out more?

See what Plant Assessor can do for your business with a demo.