Avoiding Risk Assessment Pitfalls

Plant is responsible for a huge number of workplace incidents. However well you know your machines, there’s no getting around the significant risks associated with using plant, and the major injuries, and even death, that can result from using plant that isn’t safe.

Plant risk assessments (PRA) are an important part of making sure you’re keeping yourself and your workforce safe, and your equipment in good condition. When it comes to risk assessments, it’s critical you make sure you’re getting it right, not just to keep everyone on-site healthy, but to avoid major incidents.

In this guide, we’ll break down plant risk assessments, and help you avoid some of common pitfalls.

First up, what is a plant risk assessment (PRA)?

A plant risk assessment involves a comprehensive inspection of a piece of plant or equipment to ensure it is safe for use. It is used to discover any hazards or issues with the item of plant, and to put in place the safety control measures to prevent harm; both to life, but also property and the environment.

What is involved in conducting a plant risk assessment?

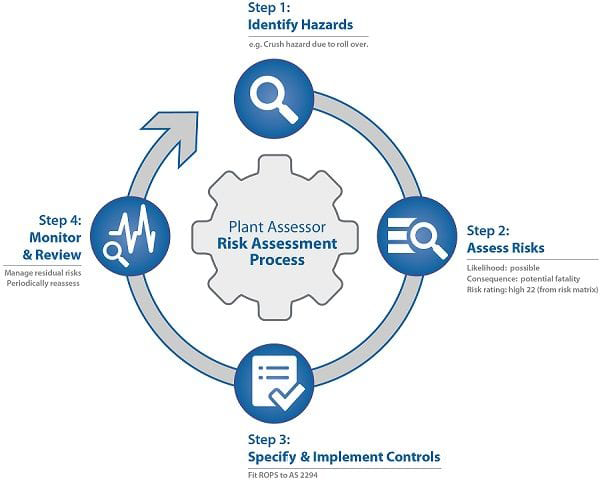

Traditionally, plant risk assessments are conducted using a 4 step process:

Step 1: identify hazards - e.g., crush hazard due to roll over.

Step 2: assess risks - e.g., likelihood = possible, consequence = potentially fatal, risk rating = high 22 (from risk matrix).

Step 3: specify and implement controls - e.g., fit ROPS to AS2294.

Step 4: monitor and review - e.g., manage residual risks and periodically reassess.

If an error or oversight is made in steps 1 to 3, this is likely to lead to fundamental flaws in the plant risk assessment.

What are the risk assessment pitfalls?

Some of the risk assessment mistakes that can be made include:

- Poor knowledge of the plant being assessed and its function

-

Poor understanding of hazards present

-

Poor understanding of the risk analysis/evaluation process

-

Poor understanding of the controls required on particular types of plant

-

Inconsistently identifying hazards, assessing risks and specifying controls

-

Failure to implement controls required by the plant risk assessment

-

Plant risk assessments that are incomprehensible, misunderstood and unusable in the field

Avoiding plant risk assessment pitfalls

The show stopper: plant safety knowledge

Manageable pitfalls: systemising the plant risk assessment process

The balance of the risk assessment pitfalls can be managed by following a systematic approach to the plant risk assessment process. A systematic approach must aim to institutionalise the knowledge required to consistently and thoroughly follow the risk assessment plan for plant. This is achieved by providing a structured process which includes sufficient guidance to assessors to reduce subjectivity, inconsistency and incompleteness, and therefore, risk assessment mistakes.

Disclaimer: This information is intended to provide general information on the subject matter. This is not intended as legal or expert advice for your specific situation. You should seek professional advice before acting or relying on the content of this information.

Ready to find out more?

See what Plant Assessor can do for your business with a demo.